In the context of the deep integration of the global economy and the transformation and upgrading of the manufacturing industry, aluminium alloy die casting products are becoming one of the core materials to promote the process of industrial modernis...

Read more

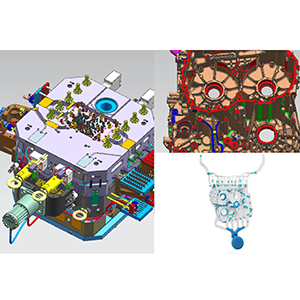

(A) advanced material research and development and application capabilities Suzhou gold Cheng closely follow the trend of high-performance aluminum alloy material research and development. The company has set up a professional material research and d...

Read more

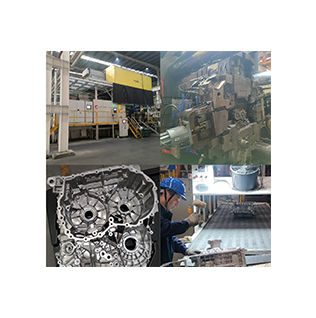

On 6th December 2024, 4000T moulds for BYD DHT32 project, independently researched and developed by Jincheng Company, were successfully put into trial production in Xuzhou Jincheng. BYD in DHT technology leading domestic, its ‘dual motor DHT hy...

Read more

Because Suzhou Jincheng Precision Casting Co., Ltd. can provide one-stop service for aluminum alloy die-casting, and its advantages may be reflected in the following aspects: 1. Full process service, higher efficiency "Design to production integration": from product design, mold manufacturing to die casting, post-treatment, surface treatment and assembly, to provide a complete solution to reduce the time and cost of customers and multiple suppliers to docking. "Shorten the delivery cycle": optimize the process through internal coordination to significantly improve production efficiency and ensure on-time delivery. 2.Technical strength and quality assurance "Advanced production equipment": We have high-precision die-casting machines, CNC machining centers and automated production lines to ensure product precision and consistency. "Rich experience and professional team": familiar with all kinds of processes and standards in the aluminum alloy die-casting industry, able to customize the best solution according to customer needs. "Strict quality control": from raw material testing to finished products leaving the factory, we set up multiple quality inspection processes, such as X-ray flaw detection, dimensional inspection, etc., to ensure that the quality of products meets or exceeds industry standards. 3.Cost Advantage "Scale production": Reduce the cost of a single piece through mass production to enhance market competitiveness. "Saving customer cost": one-stop service reduces intermediate links and lowers transportation and management costs. 4. Comprehensive process with wide coverage "Diversified process": provide finishing (such as CNC processing), surface treatment (such as spraying, plating, anodizing), assembly and packaging services for aluminum alloy die-casting products to meet customers' multiple needs. "Strong material suitability": we can choose suitable aluminum alloy materials, such as ADC12, A356, etc., according to the functional requirements of products to ensure mechanical properties and durability. 5. Customization and R&D support "Assistance in design optimization": In-depth cooperation with customers during the product development stage, we provide design improvement suggestions to optimize the mold structure and casting process. "Rapid prototyping and small batch production": to meet the needs of customers at all stages from sample development to batch production. 6. Excellent geographical location As an important base of China's manufacturing industry, Suzhou has a convenient logistics network and perfect industrial chain support, which allows us to respond quickly to the needs of domestic and foreign customers and reduce the transportation cycle and cost. 7. Flexible and efficient service "Personalized service": we can flexibly adjust the production plan and provide customized service solutions according to the different needs of customers. "Perfect after-sales support": one-stop service not only covers the production process, but also includes after-sales technical support and product optimization suggestions to enhance customer satisfaction. By providing one-stop service for aluminum alloy die casting, Suzhou Jincheng Precision Casting Co., Ltd. can help customers achieve rapid transformation from concept to product, reduce the difficulty of supply chain management, while ensuring product quality and cost competitiveness.

Read more

On November 18, the first meeting of the group standard Project working group of integrated die-casting aluminum alloy materials was held in Jincheng, Suzhou. The meeting was held online and offline at the same time, and more than 70 people participa...

Read more

On the evening of April 14, 2023, the 38th Anniversary Celebration of the Hong Kong Foundry Association and the Inauguration Ceremony of the 20th Board of Directors was held in Mankat International Hotel, Tangxia, Dongguan. More than 600 leaders and ...

Read more

On December 28, 2021, the delivery ceremony of the 10,000th unit of Taiqun Precision Machinery in 2021 was successfully held in Genesis Suzhou production base. Genesis East China marketing Director Mr. Xu Weidong and other company leaders and base re...

Read more

The 2018 China Die Casting Innovation and Development Forum and the Joint Annual Meeting of the Three Associations successfully concluded the two-day joint annual meeting of the three associations with about 700 business representatives attending the...

Read more