Les boîtes de vitesses automobiles en alliage d'aluminium moulées sous pression comportent de nombreux détails à prendre en compte lors du processus de conception et de production, qui affectent directement leur performance et leur longévité.

1. Sélection des matériaux :

1、Composition de l'alliage d'aluminium : les alliages d'aluminium couramment utilisés incluent l'ADC12 ,A380 ,A383, etc., qui présentent de bonnes propriétés mécaniques et une excellente coulabilité. La composition de l'alliage influence la résistance, la dureté et la résistance à la corrosion de la coque.

2、Traitement des alliages : un traitement thermique, comme le vieillissement, est généralement nécessaire pour améliorer la résistance et la dureté des alliages d'aluminium.

2. Procédé de fonderie sous pression :

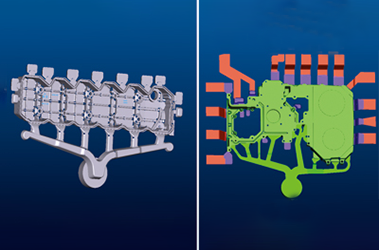

1、Conception du moule : une conception précise du moule est cruciale pour la qualité des pièces en alliage d'aluminium obtenues par fonderie sous pression. Le moule doit pouvoir résister à des températures et des pressions élevées tout en assurant la précision et la finition de surface des pièces.

2、Contrôle du processus de fonderie : Cela inclut le contrôle de la température de l'alliage d'aluminium fondu, le contrôle de la vitesse et de la pression d'injection, etc., afin de s'assurer que les pièces moulées sont denses et exemptes de porosité.

3. Conception structurelle :

1、Résistance et rigidité : la conception de la carcasse doit prendre en compte les charges mécaniques auxquelles la transmission est soumise lorsqu'elle fonctionne, il est donc nécessaire de concevoir des renforts et des zones de renforcement raisonnables.

2、Conception de dissipation de chaleur : L'alliage d'aluminium a une meilleure conductivité thermique, mais la conception doit tout de même envisager l'agencement des dissipateurs de chaleur et des orifices de ventilation pour s'assurer que la transmission peut dissiper efficacement la chaleur lorsqu'elle fonctionne à haute température.

4. Le dépôt de la demande. Traitement de surface:

1、Traitements anti-corrosion : Les surfaces en alliage d'aluminium sont souvent anodisées pour améliorer leur résistance à la corrosion et à l'usure.

2、Revêtements : Des traitements de surface tels que le pulvérisage sont parfois appliqués pour améliorer l'apparence et la durabilité.

5. Exigences de précision :

1、Précision dimensionnelle : Les pièces obtenues par moulage sous pression nécessitent un haut degré de précision pour s'assurer que les composants de la transmission s'emboîtent parfaitement. Le contrôle des tolérances dimensionnelles est crucial pour l'assemblage et les performances opérationnelles.

2、Finition de surface : Une surface lisse réduit la friction et l'usure et améliore la durée de vie des pièces.

6. Processus d'après-traitement :

1、Usinage : Certaines pièces obtenues par moulage sous pression nécessitent un usinage après le coulage, comme le perçage, l'ébarbage et le débouchage, pour répondre aux exigences finales d'assemblage.

2、Contrôle qualité : Cela inclut des essais non destructifs (par exemple, inspection par rayons X) et des tests de propriétés mécaniques pour s'assurer que chaque pièce coulée répond aux exigences de conception et aux normes de sécurité.

En concevant et en contrôlant soigneusement ces détails, on peut s'assurer que les boîtes de vitesses en aluminium moulées sous pression offriront de bonnes performances dans les applications automobiles, avec une fiabilité et une longue durée de vie.

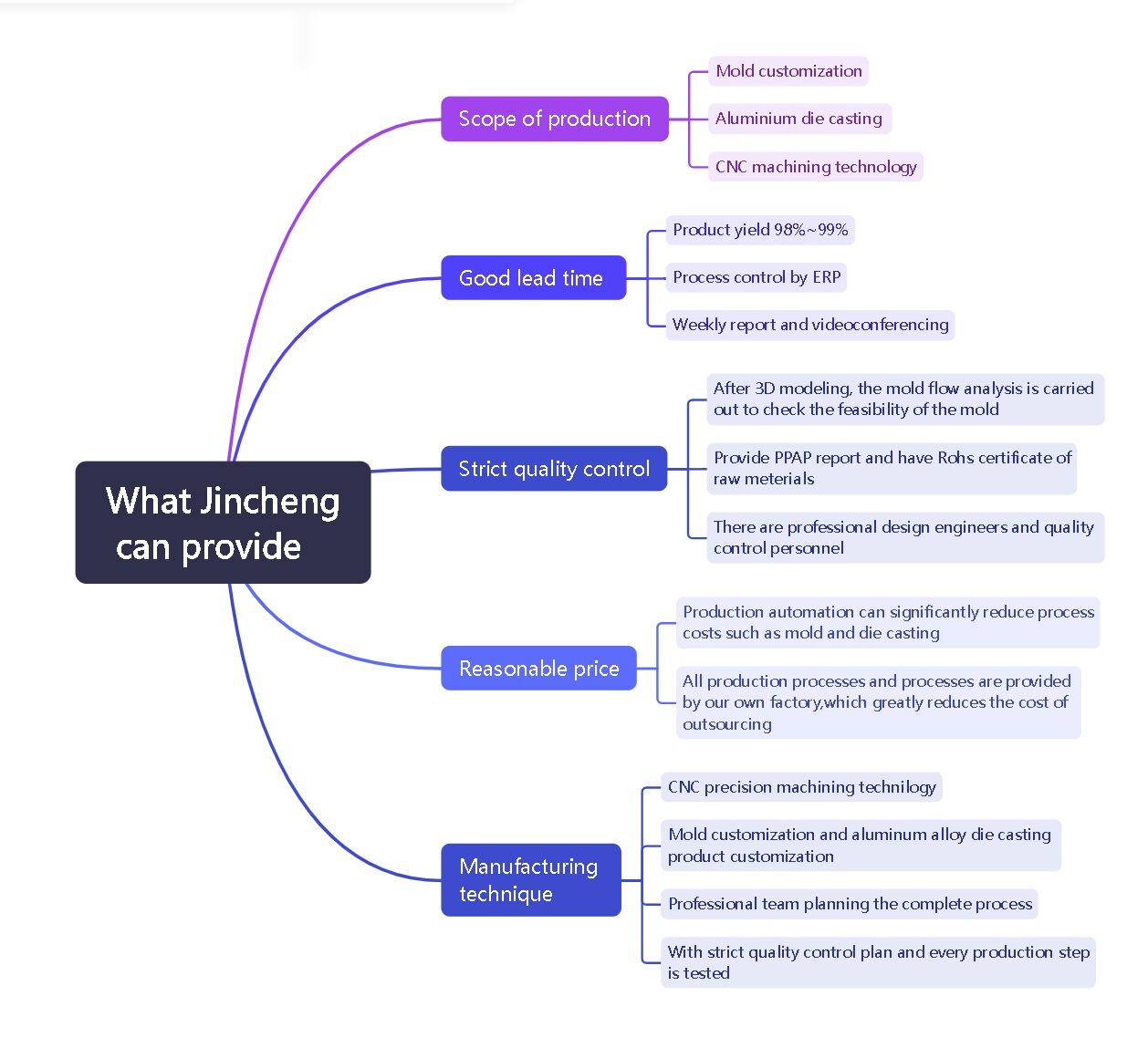

Introduction à la personnalisation des moules

En tant que fabricant de personnalisation de moules en alliage d'aluminium avec 24 ans d'expérience, nous disposons d'un processus de personnalisation parfait.

les clients n'ont qu'à fournir les dessins et les exigences de processus, tous les moules en alliage d'aluminium pour fonderie sous pression dans notre usine peuvent être personnalisés.

fabrication de moules pour fonderie sous pression

Le client fournit les dessins, et nous disposons d'ingénieurs en modélisation professionnels pour effectuer la modélisation 3D conformément aux dessins. Après la finalisation de la modélisation, une analyse de flux de moule sera réalisée pour vérifier s'il existe des problèmes dans le moule, et la production du moule sera entreprise après avoir confirmé que le moule est correct.

Elle joue un rôle crucial dans la fabrication de moules, en particulier dans le traitement des pièces de moule à haute précision et de formes complexes. Son principal rôle est le usinage à haute précision : la machine de découpe par fil peut offrir une précision de traitement extrêmement élevée, adaptée à la fabrication de cavités complexes, d'arêtes coupantes et de détails fins de moules de précision, tels que les moules de perçage, les orifices précis, les bords irréguliers, etc.

Équipement de précision pour le traitement des matériaux métalliques sans contact en utilisant le principe de décharge électrique. Son rôle principal est dans le processus de fabrication des moules, pour le façonnage fin de l'acier des moules ou d'autres matériaux métalliques difficiles à traiter, en particulier pour les cavités, trous et structures microscopiques de formes complexes et de grande dureté.

Il est principalement utilisé pour l'affûtage haute précision de la surface de la pièce afin d'atteindre la platité, la finition et la précision dimensionnelle requises.

Il offre des solutions efficaces, précises et stables pour le traitement des moules, et constitue un équipement de traitement haut de gamme indispensable dans l'industrie de fabrication des moules.

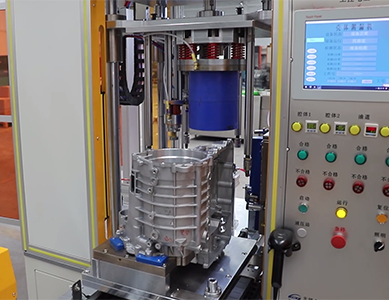

Après un processus de production rigoureux, l'achèvement final de la fabrication du moule, puis l'inspection de la qualité du moule, garantissant ainsi la qualité de la production du moule.

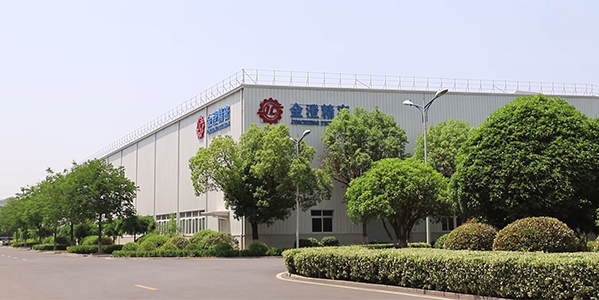

Spécialisé dans les véhicules automobiles traditionnels, les communications pour véhicules à énergie nouvelle, l'énergie photovoltaïque, le stockage, l'onduleur, le transport ferroviaire, l'aviation médicale et la fonderie sous pression en alliage d'aluminium pour pièces industrielles générales, la fabrication de moules et l'usinage de précision

La taille totale des actifs de l'entreprise a dépassé 1 milliard de yuans, couvre une superficie d'environ 200 000 mètres carrés, avec une superficie d'usine de 180 000 mètres carrés, c'est une entreprise de haute technologie qui regroupe recherche-développement et production

Fusion des alliages d'aluminium dans un four.

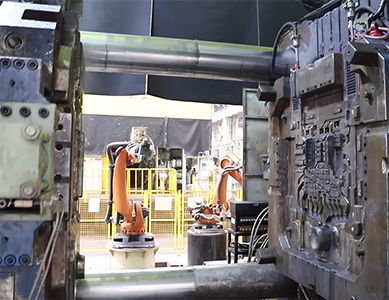

fonderie sous pression de 4000T en fonctionnement

Préparation des moules dans les machines de fonderie sous pression

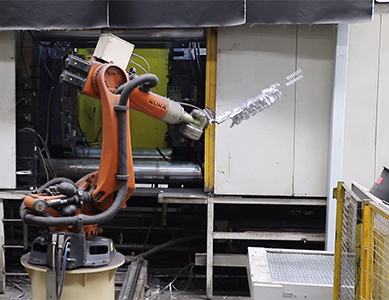

Produits d'extraction par bras robotisé

Polissage maître des produits par les travailleurs

Machine à sablage pour réaliser le travail et intégrer le produit

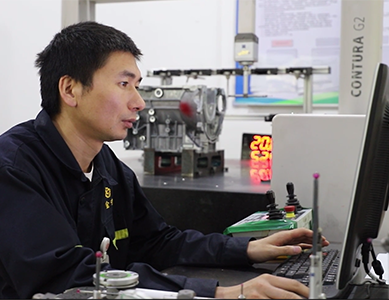

Contrôle de la qualité du produit en laboratoire. Test des ingrédients du produit

Vérification des dimensions du produit

Équipement d'immersion pour tester l'étanchéité des produits

Test d'étanchéité à l'eau pour détecter l'étanchéité des produits

Le test d'étanchéité détecte l'étanchéité des produits

Nettoyage ultrasonore des surfaces de produit pour les garder propres

| 1. Avantage technique | 1. Experts de l'industrie de la fonderie sous pression plus de 20 personnes, ingénieurs professionnels en moules plus de 80 personnes ; 2. Conception 3D, analyse du flux de moule, fabrication de moule, analyse du procédé de fonderie sous pression (service sur mesure) |

| 2. Avantage de surveillance de la qualité | 1. Plus de 10 ingénieurs qualité, équipe spéciale de contrôle qualité; 2. Le nombre d'équipements de test est de 10; 3. Certification : ISO9001:2008 système de certification de la qualité internationale ; ISO14001:2004 certification du système ; ISO/TS16949:2002 certification du système de qualité de l'industrie automobile ; |

| 3. Avantages de la fabrication des moules | 1. Ingénieur en conception de moules, peut utiliser les logiciels PRO-E, VG et autres; 2. Équipements avancés, centre d'usinage HAAS, fraiseuse CNC à portique, etc., plus de 49 équipements, une production annuelle de 300 ensembles de moules de fonderie sous pression ; 3. Nous pouvons concevoir des moules pour les clients (fournir des services sur mesure) |

| 4. Avantages de la fabrication de fonderie sous pression | 1. 57 lignes de production, avec une capacité annuelle de 50000 tonnes de pièces en alliage d'aluminium obtenues par fonderie sous pression ; 2. Niveau de production intelligent : machine à soupe automatique, machine à pulvérisation automatique, machine de prise automatique, bande transporteuse automatique, machine de refroidissement à point haute pression, équipement de découpe et de mise en forme ; 3. Conception de produit flexible, fournissant des solutions de production, créant des conditions pour une production en petites séries |

| 5. Machine plus avantage de fabrication |

1. Plus de 600 ensembles de machines-outils CNC et plus de 60 ensembles de centres d'usinage horizontaux; 2. Ingénieurs programmeurs d'usinage CNC au total 30 personnes, 30 ingénieurs et techniciens de projet; |

| 6. Traitement de surface avantages technologiques |

1. Entreprise de sous-traitance de pulvérisation indépendante; 2. Atelier de pulvérisation sans poussière de cent mille, trois lignes de pulvérisation, douze pistolets de pulvérisation électrostatique importés, quatre lignes de production de galvanisation automatiques, deux lignes de production de prétraitement; 3. Équipements complets de test de pulvérisation et de galvanisation; |

| 7. Installation de soutien | 1. Atelier propre : atelier propre GP12 de 1000 mètres carrés ; 2. Station de surveillance des produits ; 3. Équipement de test d'étanchéité à l'air ; 4. Équipement d'infiltration ; 5. Machine de nettoyage automatique des produits ; |