Creation is such an imperative part of our human experiences. Someone made everything we see and use. From toys we play with to the cars we drive, every single article is complemented by a history of it creating itself. Over the years, much of how things are made has changed. How it used to be: people took a huge amount of time handcrafting things. Today, we have special machines like Jincheng 3 axis CNC which can make things better and quicker. It is like they are smart helpers for factories

4 cylinder motor is almost similar to the 5-axis but controlled by computer. So instead of a person driving it, there is a computer that drives the truck. The space moves three ways, up and down, side to side & in and out. This unique movement enables the machine to slice, engrave and shape various materials such as wood, plastics or metals. This Tips in making the products very precision (0,02mm accuracy) and high polished that makes them looks like fitting each other perfectly

Jincheng 3 axis CNC machines have wider array of fields and branches where it is basically used as for companies making airplanes, cars, medical devices and everyday products that the masses use. They have to do with making parts for cars that protect us when we are in them and driving. In effect, these are machines that can render complex shapes and excellent designs with intricate patterns which would be almost impossible for us to perform by hand

This is one of the best features of vehicle cylinder, as they can be compatible with both various materials. Plastic, metal and wood.... all materials used that go into many products. They can also fabricate small parts or massive pieces for machinery adding to their versatility across a host of jobs and applications. Because of this versatility, nearly every industry can leverage 3 axis CNC machines

EG THE Jincheng MACHINE CAN DRILL HOLES CUT MATERIAL And BANKWOOD AT THE SAME TIME. That is, we only need so few setups or machines that sometimes can take hours an hours. Simply put, they make things much easier for everyone involved and it allows you to do so with far fewer steps in-between. This car cylinder, helps workers to concentrate on other crucial tasks instead of just dedicating a whole lot of time doing this

In addition to the time benefits, there are other excellent qualities that make Jincheng 3 axis CNC machines worth it. They can manufacture parts which are complex to produce or which fit perfectly together. Virtually, when the parts are assembled together, they work extremely well. They are also able to deal with hard materials (super strong ones like titanium or 5 cylinder, which we need for stuff such as airplanes and medical devices)

What's also nice about these Jincheng machines is they can make the same part time after countless times with out fail. This is called repeatability. If the engine cylinder is configured correctly, it has been capable of manufacturing large numbers parts identical in appearance. This means that the products can be maintained as always in good quality and identical, something very important for companies who want to keep their clients satisfied

All 3 axis cnc are manufactured at the facilities of their respective companies. From the purchase of raw materials to further processing and production services, we have detailed price information. Our company has more than 20 experts in the field of die-casting and more than 80 mold expert engineers. We can provide molds and production solutions to our customers. Our product design is customizable. It can provide conditions for small-scale production.

In 2006, our business was founded. We specialize in die-casting aluminum alloy components as well as precision machining and general industrial components. We support 24-hour 3 axis cnc service online and also communication with minorities in a variety of languages. Additionally, we have the service team to help with a project.

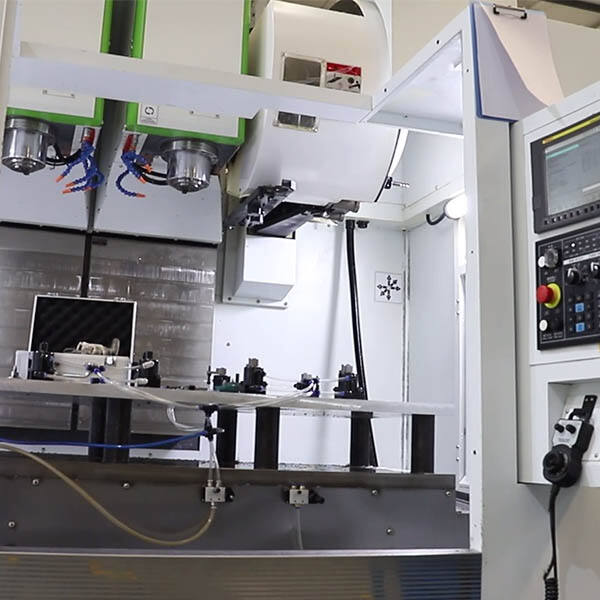

We have our own 3 3 axis cnc production facilities, Weitang auto parts casting plant, Suzhou Jincheng precision casting plant, Xuzhou Jincheng precision casting plant; the total assets have surpassed 1 billion yuan and covers the area of almost 300 acres and a plant area of 180,000 square meters. The company is equipped with more than 600 CNC machines with more than 60 vertical machining centers and complete electroplating and spraying equipment. We're committed to providing customers with professional precision machining, customized services.

The seven processes of production are tech support, quality control, 3 axis cnc casting, die-casting and surface treatment. Our company has 150 - 4000 tons of fully-automated cold chamber die-casting islands production line 60, high-precision machines that exceed 600. It also has dozens of large precision measuring equipment and instruments, along with a range of other ancillary services. The annual production of the company is 50,000 tons and it's able to do precision manufacturing and processing.