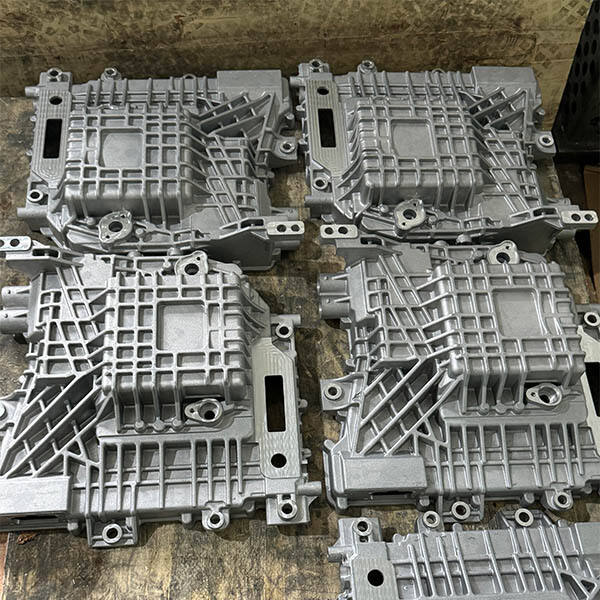

WHAT ARE ALUMINUM DIE CASTING PARTS?

These parts are incredibly beneficial and find applications across a host of industries for good reason. This article will detail the many advantages of using Jincheng aluminium die casting parts in addition to how they are produced, where they can be found today and exactly what you need to produce an outstanding part made from aluminium when utilising the process for die-casting.

There are many benefits that aluminum die casting parts have, and this is why they remain popular across so different industries. For starters, they are ultra-light and super portable which makes them very easy to transport for shaping odd shaped components. This process also makes them more workable during fabrication. Secondly, these aluminum die casting parts have high heat conductivity So they are good for things that make heat, like engines or electronics. Aluminium die casting parts third is anti-corrosion and rust. This is what makes them withstand harsh conditions for a long time. Also, they are heavy conductors electricity and so used to made any electrical parts which should be connected with proper conduction.

High Pressure die Casting is a particular type of process to manufacture parts. Here, the molten aluminum is injected into a mold under high pressure. A mold consists of two parts, which are the die and core. This ensures that the melted aluminium flows across a small orifice known as gate and takes up the shape of entire die. But as the Aluminium cools and solidifies, then mold is opened again and part removed. This cycle can be repeated many times to build all the same part relatively quickly and efficiently. The Jincheng die cast aluminum parts is a useful way to create large numbers of the same part.

There are many industries where aluminium die casting parts have use in the automotive industry, aerospace and electronics etc. Such components are getting used very generally in automotive enterprise to fabricate those crucial parts like engine blocks, transmission cases and oil pans. All of these work together to keep a vehicle running right and efficiently. The importance of aluminium die casting in the aerospace industry: In making these parts, it is not possible to ignore aluminum processing since wings, fuselages and engine components are structural elements that cannot be realized without them. These parts need to be very strong whilst at the same time lightweight in order for them to maintain safety and performance fly flight. They are used in the electronics industry to form almost all of the components for computers and communication devices. Such aluminium die castings include parts such as heat sinks, housing and connectors which are necessary for electronic gadgets to be fully functional.

Die casting is good for manufacturers as it has many environmental benefits. The first is economical in that it requires less material than other production methods. It also enables cost-savings for companies, without compromising on quality parts. Secondly, the die casting process produces less waste and is environmentally friendly which limits any damage to the environment. The third feature of aluminum die-casting parts is high service life, and the need for replacement will be less frequently, which saves resources. The fourth, it is easy to be recycled by the return of these parts has prevented a large amount from entering landfills. Lastly, this manufacturing process consumes very less energy thus lowering the greenhouse gas emissions and making die casting one of the most environment-friendly processes.

Using die casting to create a high-quality aluminium part takes careful consideration in several key areas. Design of the part - Which shows detailed size and features of the component. This template shall contain all required information like height, dimension and features etc. Second, the perfect die casting method will have to be chosen for your requirements. The two main types of die casting are hot chamber die casting and cold chamber die casting. These different methods have their advantages and fit for a certain use-case. Common aluminum alloys are used, each one of the having different properties and uses. Third is to pick out the right type of aluminum alloy, which most crucial as this refers differences in across all parts etc This decision will vary as per use. If there is to be any post-production on the part, you should choose this way of completing it next and that works under all limits. Finally, inspect the mould for aluminium casting section of Jincheng carefully to ensure that it meets all necessary specifications and is ready for use.

7 production process, technical support quality control, mold production, die casting production, machine production, surface treatment process, supporting facilities. Our company is equipped with 60 modern precision machining centers and fully automated cold chamber island die-casting production lines ranging between 150 and 4000 tonnes. The company also has dozens of large precision instruments and measuring equipment, as well as various related services. The Aluminium die casting components production of the company is 50,000 tons, and it can perform precision manufacturing and processing.

In 2006, our business was founded. We specialize in die-casting aluminum alloy components as well as precision machining and general industrial components. We support 24-hour Aluminium die casting components service online and also communication with minorities in a variety of languages. Additionally, we have the service team to help with a project.

The product is manufactured by their own factories. From the purchase of raw materials to further processing and production services we provide Aluminium die casting components details. The company is equipped with more than 20 experts in the field of die-casting and more than 80 mold professional engineers. Our product design is flexible, we can design molds for our customers and offer solutions for production. It will provide the right conditions to produce small batches.

Aluminium die casting components of our production sites: Weitang auto part casting plant, Suzhou Jincheng Precision Casting Plant, Xuzhou Jincheng Precision Casting Plant. The total assets are more than 1 billion Yuan and covers 300 acres. The plant is spread over 180,000 square meters. The company boasts over 600 CNC machines and 60 horizontal machining centers as well as complete electroplating and spraying testing equipment. We're committed to supplying customers with professional precision machining and customized services.