Aluminium metal an amazing material involved in many of our daily activities. Aluminum is found in all kinds of things, such as kitchen utensils (like the ones below) and cans or even airplane parts! Aluminum is an element that has some unique properties which make it useful in various forms. The following article is about the advantages of aluminium, what applications it can be used in which projects and how it helps the environment as well some factory use case studies that aluminum are replacing iron or steel.

Aluminum is very light in weight, which makes it easy to handle and use. It is light weight but at the same time, incredibly strong. It is highly durable and non-corrosive, vis-a-vis it's a preferable choice for many products being sold in the market today. Jincheng cnc metal lathe can be used for many things such as cars, trains, and packages. As well as its easily molded nature means that it can be created in all shapes and sizes for whatever use. For instance, it can be produced in thin sheets for packaging or tough and firm components for cars.

Aluminum metal is so versatile that its in almost Everything. It is used in the transportation industry, construction and even electronics. Jincheng Products is used in cars, planes and even big buildings like bridges. It is everywhere! You may also find it in appliances such as refrigerators, microwaves and even the foil that we use in our kitchens. This sheds light on the constant use of aluminium metal and where it can be utilized in our lives.

Significance: One of the major contributions to safeguarding the environment is aluminum metal. Aluminum is a pretty good conductor of electricity, which makes this great for the job. For that reason, Jincheng metal cnc machine is commonly used in solar panels and helps to generate clean energy from the sun. This is far cleaner for the planet because it does not provide energy to run polluting fossil fuels. With the added bonus that aluminium also enables greener electric cars to be built - as it is light, helping to reduce energy consumption and pollution from their use. Aluminium use, thus helps indirectly in reducing the harmful effects on our nature and you can help to make this earth a little cleaner with it.

Aluminium metal is one of the features, which have made it useful for such applications. Its lightweight nature is not the only benefit; it is also strong and resistant to corrosion So, it is good for producing airplane parts, car bodies and soda cans. Due to its excellent conductivity, copper is also found in electrical wiring and power generators as well. Another plus of aluminium is that it can be easily recycled, in this way we can renew to use as much as we want without getting worse.

This is a huge victory for manufacturers that are using the aluminium metal in their factories. The Element aluminium is malleable, which means it can be made into many different products. It helps reduce the weight, as in transportation products. An example of this is the use, for airplanes manufacture, lighter metals such as aluminium in lieu of heaver ones due to result light weight aeroplanes which can take-off more easily and consume less fuel. This saves money for the airlines and is better on fuel consumption, which in turn benefits our environment.

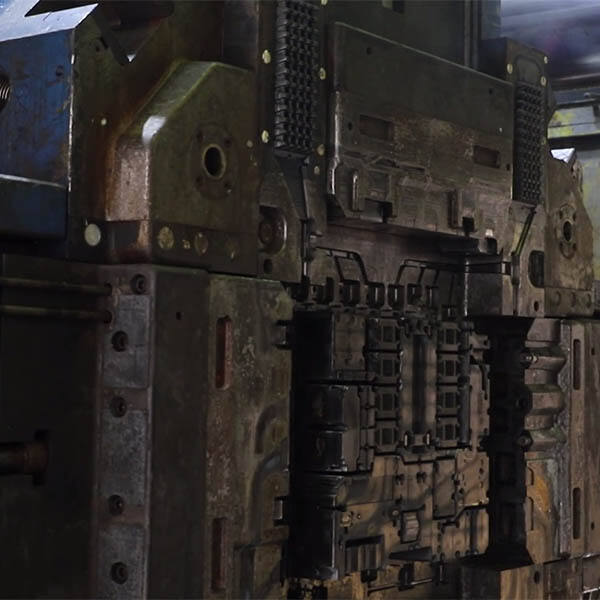

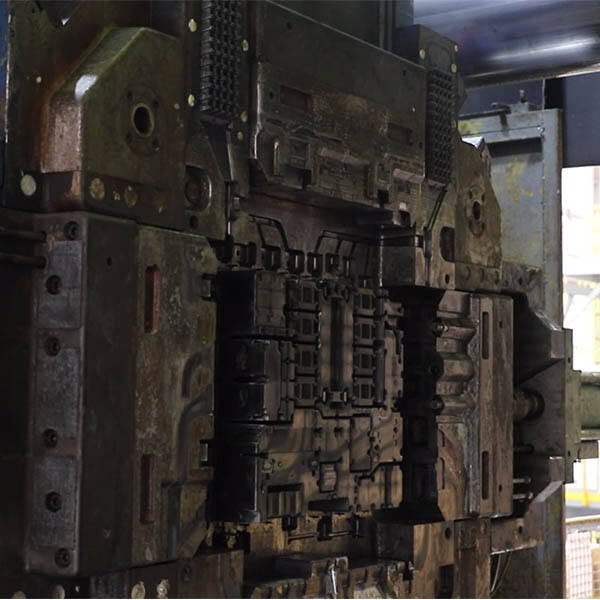

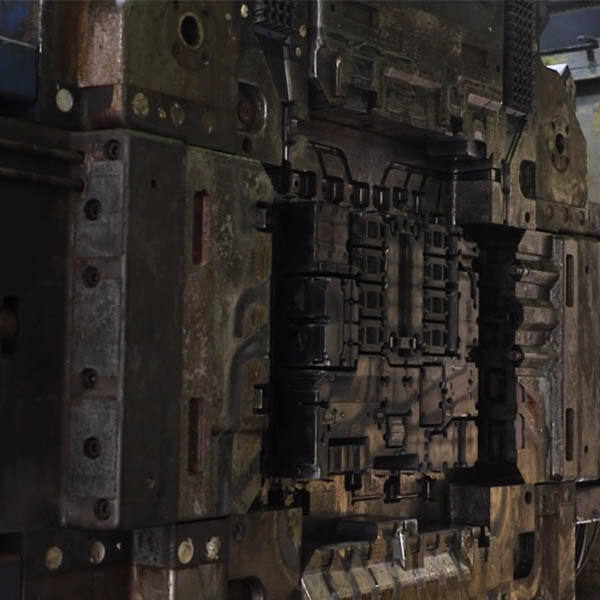

7 production process, technical support, quality inspection, mold making die casting production, machine production surface treatment, and supporting facilities. Our company has Aluminium metal machining centers, completely automatic cold chamber island die-casting production lines ranging from 150 - 4000 tons. The company also has various ancillary facilities and numerous large-scale precision measurement equipment and instruments, with an annual production of 50,000 tons of aluminum alloy die casting parts and parts research and development production and precision processing capabilities to get the impact of large-scale production.

The products are produced by the company's own facilities. We have all the details about prices, ranging from raw materials to production and even services. The company is Aluminium metal with more than 20 die-casting industry experts and over 80 mold professional engineers. We can provide molds and production solutions for our customers. Our product design is customizable. It is able to provide the conditions needed to produce small batches.

We have our own 3 Aluminium metal production facilities, Weitang auto parts casting plant, Suzhou Jincheng precision casting plant, Xuzhou Jincheng precision casting plant; the total assets have surpassed 1 billion yuan and covers the area of almost 300 acres and a plant area of 180,000 square meters. The company is equipped with more than 600 CNC machines with more than 60 vertical machining centers and complete electroplating and spraying equipment. We're committed to providing customers with professional precision machining, customized services.

Our company was established in 2006. was founded. We specialize in die-casting aluminum alloys as well as Aluminium metal machining and general industrial components. We provide human-powered online service throughout the day, and communicate in languages of minorities. We also have the service team to help with a project.