Casting, Casting Product and Aluminum MetalAluminum is a special metal that can be used to make many different things. Casting, in which aluminum is melted and poured into a mold; Jincheng aluminium die castings is a new object later when it cools. It also empowers manufacturers to create numerous products that range in size from tiny parts to vast components. One is that you get a light, durable and long-lasting part as such aluminium casting parts really do make something more full-proof. Aluminum is a vital material used for many things in countless industries, from crockery to aircraft parts.

One good thing about this is that it is really light, being aluminum. So it's ideal for parts on planes, cars or bicycles. Lighter things burn less fuel, works better. Some examples can be found in the more efficient flight allowed by lighter airplane parts, that results to less money spent on fuel. This, of course is important for the manufacturers and as well as those customers who drive these vehicles.

Aluminum parts Additionally, they are known for being incredibly strong. That makes it much more difficult to break than most other metals, which with no bending property has steel falls at the first place. This die casting is imperative, particularly for long-term parts (especially in hostile conditions/cgi). By this we mean that car parts built out of aluminum are anathema to cracks and pressure within bumps, making them dependable over time.

Here are a few things to keep in mind about aluminum casting if you want o know more. First of all, there are alloys-various types of mixes in aluminum. Every Everwear alloy has unique properties and applications. For certain applications there are also various alloys that work better, and can produce stronger or lighter parts. Understanding these alloys can give you more pointers on which to punch for the job

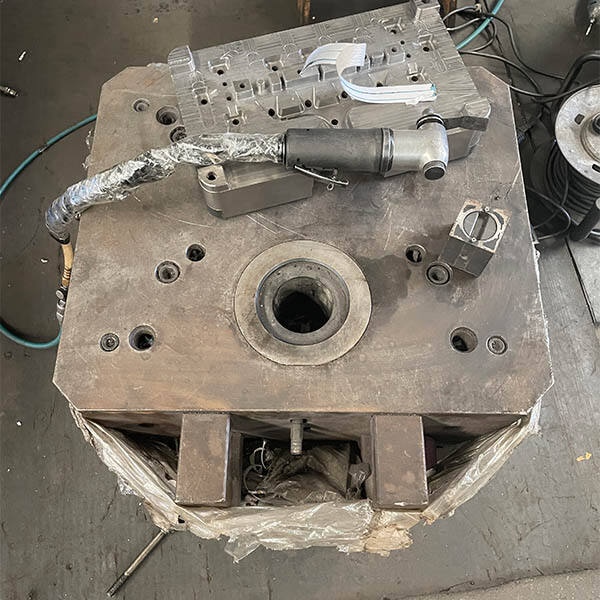

Second, we can cast aluminum parts in different ways. Jincheng aluminium casting parts is one of the oldest and most well-known methods Another old method Permanent mold casting Die casting Classifications. And both of them have some pros and cons are there, so you should choose that according to your need. Here are some examples: Sand casting if for slightly larger components than die-casting and also maybe not of very fine tolerance as in the case of die-castings which can be used to covert those miniaturistic parts you have dreamed making while aware. This knowledge will allow you to choose wisely when picking aluminum components.

You can deal with the same depth by utilizing aluminum casting parts, you could trust that they will be robust and reliable. Aluminum is not prone to rust, and will never disintegrate over time. Makes it perfect for outdoor uses or wet locations. For instance, aluminium die casting parts that are used for outdoor furniture or garden tools can act as a barrier between the metals and ensure they will not come into contact with one another to prevent damages.

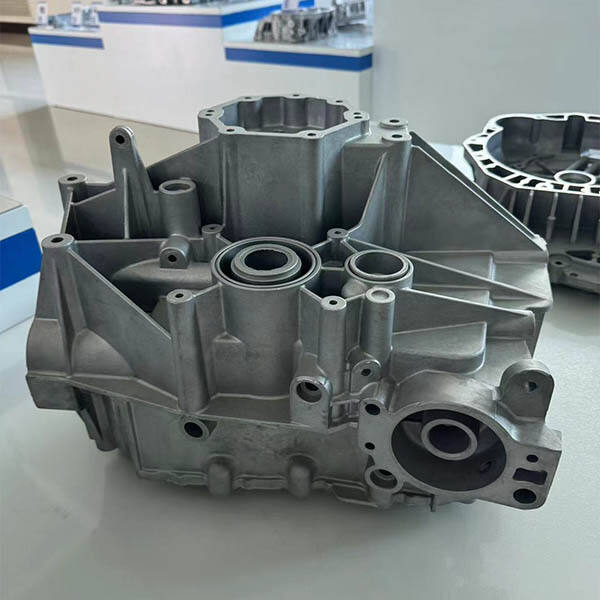

In Addition to That, Jincheng aluminum die casting parts are Made Up Very Carefully. All parts would be the same when to make a mold This level of precision guarantees that every component will fit precisely as designed and operate like it should. This translates some security, you can trust that each component will function as they should and cover their part for the final functional item to work properly for a long time.

The products are made in the factories of the respective companies. We provide all the information on prices, from raw materials to production and even services. More than 80 mold engineers and Aluminum casting parts die-casting experts are in the company. Our product design is flexible and we are able to design molds for customers and provide production solutions. It can be used for small-batch production.

7 production process, technical support, quality inspection, mold making die-casting production, production of machines Aluminum casting parts, and supporting facilities. Our company boasts 150 - 4000 tonnes of fully automated cold chamber die-casting island production line 60, and advanced precision machining centers more than 600. The company also owns a plethora of high-precision measuring instruments and equipment and a variety of ancillary services. The annual production of the company is 50,000 tons and it is able to perform precise processing and production.

Our company was established in 2006. was founded. We specialize in die-casting aluminum alloys as well as Aluminum casting parts machining and general industrial components. We provide human-powered online service throughout the day, and communicate in languages of minorities. We also have the service team to help with a project.

We own three important production facilities, Weitang Aluminum casting parts casting plant, Suzhou Jincheng precision casting plant, Xuzhou Jincheng precision casting plant. The total asset size has exceeded 1 billion yuan and covers the area of almost 300 acres, plant area that is 180,000 square meters. The company is equipped with over 600 CNC machines and more than 60 horizontal machines, as well as a full electroplating and spraying equipment. We're dedicated to providing our customers with the highest quality precision machining customized services.