Today, we have something very interesting to study- CNC Machines. CNC machine Have you heard of it? 1) CNC: Stands for Computer Numerical Control. The Jincheng fact that they are computer based, which is really unique. So, they are capable of the performance to do amazing things like cutting and carving down all kinds of objects. In this article we will go through different CNC machine types and understand what makes them unique in their applications!

CNC Milling Machines

CNC milling machines are designed to carve solid materials, including metal and wood or plastics. They are somewhat common in manufacturing like cars, airplane or medical equipment. The cnc engine block unique tools that CNC milling machines rely on is what makes them able to cut and shape materials in the extreme precision they do.

CNC milling devices are supported in making exact cuts. But that gives them the ability to shape materials however they wish. Computerized embroidery machines, allows for many more creative patterns and drawings to easily be created. This cnc machining is why industries such as automotive and aerospace depend upon CNC milling machines to provide consistent parts that correctly fit together. These Jincheng machines which work with accuracy are used to design the safe and operational level of products.

CNC lathes utilize different tools to reshape materials into unique shapes. Horizontal type, vertical type universal and compound of CNC lathes. This makes them better fit for specific type of tasks as every time has different advantages and privacy over the other. For example, you may find that some lathes are better suited for larger pieces whereas others might be excellent around more intricate smaller tasks. You are just choosing the right machine for each job!

CNC Plasma Cutting

CNC Plasma Cutting is an interesting way to cut them but the plasma does not refer blood in this case. To clean a metal surface, you generally use plasma which Jincheng is pressurized and can simultaneously heat up to very high temperatures. It cnc milling machine is a widespread method in industries like automotive, construction and design. It makes use of special gases and electricity which to generate plasma, used for cutting efficiently by CNC (computerized numerical control) controlled machines.

There are many benefits that can easily use CNC plasma cutting machines. They can slice through materials fast while maintaining accuracy, One how much better they are for those expert works. However, using these machines have cons as well. For instance, they make a lot of noise, have exhaust fumes and are expensive to run. For these cnc lathe, CNC plasma cutting machines are usually located in large factories and industrial settings.

CNC Routers

CNC routers - which, as the name suggests, are machines powered by CNC technology that can cut and shape materials such as wood, plastic and metal. They cnc mill are most popular in industries where furniture, cabinets and signage is manufactured. Like the other machines we have discussed CNC routers use special cutting tools to help enable their operation

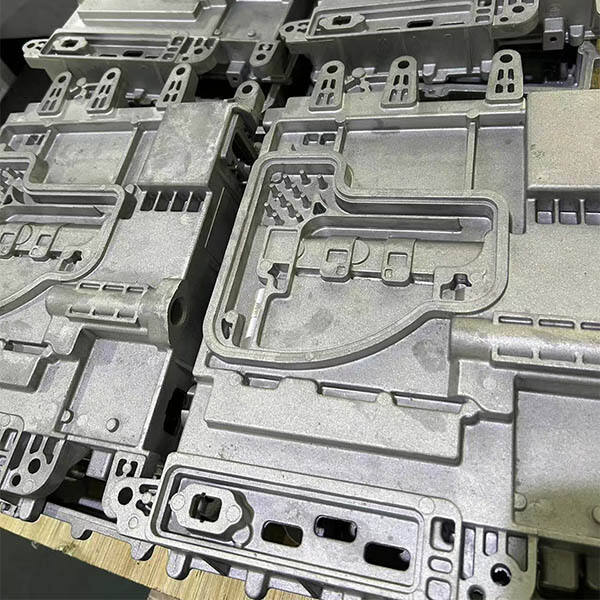

We have our own 3 important production facilities, Weitang auto parts casting plant, Suzhou Jincheng Cnc types, Xuzhou Jincheng precision casting plant; the total value of the assets is more than 1 billion yuan, covers an area of nearly 300 acres, and has a plant space that is 180,000 square meters. The company has over 600 CNC machines with more than 60 vertical CNC machining centers, and a complete spraying, electroplating testing equipment. We offer professional precision machining services that are tailored for our clients.

Each product is manufactured at the Cnc types of the respective companies. We have all the details about prices, ranging from raw materials to production and services. More than 80 expert mold engineers as well as 20 die-casting experts are available at the company. Our product design is nimble, we can design molds to meet the needs of our customers, and also provide production solutions. It is suitable in small-batch production.

In 2006, our business was established in the year 2006. We are Cnc types in die-casting aluminum alloy pieces as well as precision machining and general industrial components. We provide online human service all day, every day. We also communicate in a variety of languages. We can also offer a team of service representatives to work with your project.

The seven processes of production are tech support, quality control, Cnc types casting, die-casting and surface treatment. Our company has 150 - 4000 tons of fully-automated cold chamber die-casting islands production line 60, high-precision machines that exceed 600. It also has dozens of large precision measuring equipment and instruments, along with a range of other ancillary services. The annual production of the company is 50,000 tons and it's able to do precision manufacturing and processing.