The casting of products for cars is very interesting. This helps in saving time and produces parts quickly which are also very strong. One such method is die casting to produce car parts. The quick pace at this thing can make several components simultaneously and more. Jincheng die casting automotive parts also produces strong parts that are difficult to break. Metal must be subjected to heat until the material reaches liquid state. This liquid metal is then poured into a mold which forms the part.

It took a long time to make car parts and cost only when die casting was invented. The existing methods carried out by car companies involve forging and stamping parts one at a time. That translated to a long lead time for getting enough parts built just to make one car. Jincheng die casting car parts highlight changed the course and all for good. With molten metal to pour into molds, car companies could then make many more parts than before in an even shorter amount of time. The process of die casting also facilitated the assembly processes, so that entire cars could be assembled quickly and economically.

A car has different components that are required to work together in sync. In their engineering process, quality control checks each part to ensure that it had been made correctly and functions as expected. Jincheng die casting solves this problem by producing parts that are a consistent piece every time. Because the metal is melted and then poured into molds, every piece comes out with a uniform shape and size. This gives car makers more control and helps them make better, safer cars for all of us!

When it comes to making car parts, die casting can use various metals, though aluminum is the choice of most automotive companies. This is because aluminum is lightweight. Cars have to weigh low so as they can go fast, but at the same time need sturdy design element for safety. Aluminum allows automakers to produce strong but light parts. This allows them to move faster and protects people inside the car. The die cast aluminum parts doesn't rust so things built from it will last and always keep its shine!

The first thought that might come to your mind is what kind of parts are created by die casting. Engine blocks, transmission cases, and wheels can all be made through aluminum die casting parts. Even smaller components can be formed using SLM. It illustrates how crucial die casting is to the production of each part on a vehicle. Cars would be longer to produce, more expensive and less safe for drivers and their passengers without die casting.

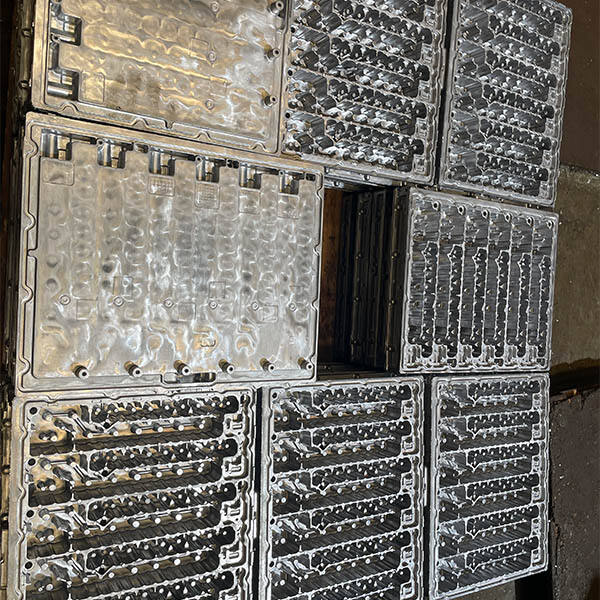

The seven production processes include the following: technical support, quality control, mold-making die-casting, machine production and surface treatment. Our company Die casting auto parts 150 - 4000 tons of fully automatic cold chamber die-casting production lines 60, and advanced precision CNC machining centers with more than 600. The company also owns a plethora of high-precision instruments and measuring equipment, as well as various additional services. Its annual production is 50,000 tons and it's able to do precision processing and production.

Our company was founded in 2006, and is specialized in Die casting auto parts, modern technology vehicles for energy, telecommunications, photovoltaic energy storage, inverter, medical, rail aviation, and other custom aluminum alloy die-casting components and precision machining as well as general industrial parts. We offer 24 hours of human-to-human online service as well as communication in minor languages. We can also provide representatives from our service department to help you with your project.

Each product is manufactured at the Die casting auto parts of the respective companies. We have all the details about prices, ranging from raw materials to production and services. More than 80 expert mold engineers as well as 20 die-casting experts are available at the company. Our product design is nimble, we can design molds to meet the needs of our customers, and also provide production solutions. It is suitable in small-batch production.

We have our own 3 major Die casting auto parts, Weitang auto parts casting plant, Suzhou Jincheng precision casting plant, Xuzhou Jincheng precision casting plant; the total asset size has exceeded 1 billion yuan and covers an area of more than 300 acres, and has a plant space that is 180,000 square meters. The plant has over 600 CNC machines with more than 60 vertical machining centers as well as complete electroplating, spraying and testing equipment. We offer professional precision machining solutions that are customized to our customers.