A Jincheng gearbox casing is one of those parts that have their importance on a car. Why is it required for a car to run smoothly and efficiently? It will be clear in the following essay. An almost outer shell over your organs that can treat some problems should things start going a little bit wonky. That keeps the gears close to themselves which is very useful. The gearbox house sits in a casing and is not directly involved with the actual gears, it allows each pair of meshing gear wheels to slide into place when they need more power(faster) or less speed(slow down), by pressing on other pedals such as gas pedal (for acceleration); gear lever or brakes (to brake). This can mean the car will be far quicker to respond and therefore give its all on-road

So when it comes to searching for the very best qualities that need in order to make your aluminium die castings last longer First, It must be built from solid materials like Stainless-steel or Aluminium. Those things are pretty much indestructible and take heaps of punishment. The Jincheng casing also needs to be able not only withstand high temperances, but it cannot shatter or break in any manner. They will eventually experience the same sort of issues once it hits boiling. Besides, there is supposed to be air coming in from it. It can cool the gearbox casing, then because fresh air is what jack in to it while you are on a run

There are two main Jincheng gearbox casings: manual and automatic. You depress another little pedal and take one of those sticks to change gears if it has a manual Consequently the driver literally is able to drive as he wishes. With an automatic gearbox, on the other hand, there is no need of changing gears for a driver. This is good but when one drives in very slow traffic, this makes for a comfortable drive. engine cylinder: There are numerous kinds of Automatic gearboxes, for example- Continuously variable transmission i., Dual-clutch transmission DCT. Some are best suited for a typical fitment while others offer features and characteristics that appeal to the participant. Those who like to have more control, they can use the manual gearbox and for those lazy bums there is an automatic unit that provides comfort

Jincheng Gearbox Housing Maintenance and Repair This is done by checking the gearbox oil levels to ensure adequate lubrication, normalisation or burnt out of the old one. In this case, you also have to maintain a clean clutch housing that keeps out the dirt or foreign particles. Yet it could cause dust pile-up complexities as well. The replacement of gearbox casing should be carried out only by a trusted mechanic. Only an experienced transmission mechanic will be able diagnose and cure the issue

The technology utilised in the Jincheng gearbox casing has really come on a long way since its original conception. A manual transmission used to be basic, and also quite heavy as well thanks tough old cast iron or brass guts. They were strong but very heavy materials. Thus, as the technology has continued to grow and evolve rapidly with time so these gear box casings began being created from a lighter substance that is difficult like aluminum which naturally makes them easier for you in handling logistics during installation. The car battery cover today are even more advanced. Plus, a good many use computer-controlled sensors and actuators to see how the transmission is performing. This means the car functions with less interruptions, and more of these things are adjusted as-the-car is operating

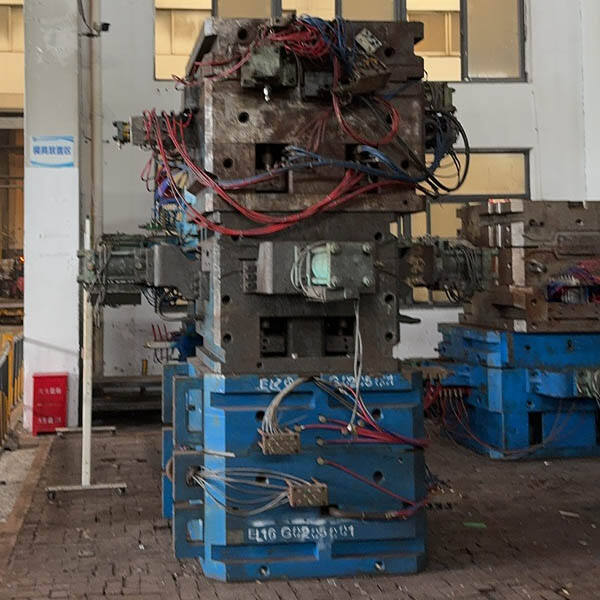

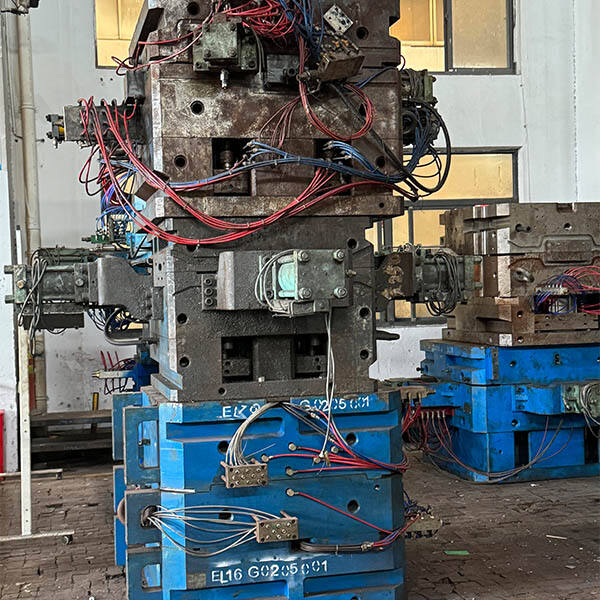

We have three production facilities: Weitang auto part Gearbox casing, Suzhou Jincheng Precision Casting Plant, Xuzhou Jincheng Precision Casting Plant. The total assets of the company exceed 1 billion Yuan and covers an area of 300 acres. Our facility covers 180,000 square metres. The company boasts over 600 CNC machines with 60 horizontal machining centers as well as complete electroplating and spraying testing equipment. We're committed to supplying our customers with high-quality custom machining services.

The seven production processes include the following: technical support, quality control, mold-making die-casting, machine production and surface treatment. Our company Gearbox casing 150 - 4000 tons of fully automatic cold chamber die-casting production lines 60, and advanced precision CNC machining centers with more than 600. The company also owns a plethora of high-precision instruments and measuring equipment, as well as various additional services. Its annual production is 50,000 tons and it's able to do precision processing and production.

The Gearbox casing was founded by a group of people in 2006. We specialize in traditional automobiles, new energy vehicles, telecommunications photovoltaic energy storage, inverter rail transit, medical aviation, as well as other custom parts made of aluminum alloy, as well as precision machining and general industrial parts. We provide online human service throughout the day, and communicate in minorities languages. We also can provide a team of service representatives to work with your project.

The product is manufactured by their own factories. From the purchase of raw materials to further processing and production services we provide Gearbox casing details. The company is equipped with more than 20 experts in the field of die-casting and more than 80 mold professional engineers. Our product design is flexible, we can design molds for our customers and offer solutions for production. It will provide the right conditions to produce small batches.