Earlier, lots of people used to work in factories manufacturing goods by using their physical labour. They spent hours creating products one byproducts. But that cnc machining work has long since migrated to machines. These Jincheng are the types of machines that do some lifting when somebody else can not, as well as they move things. Machines also perform many of the tasks that people would have to do, like hoisting heavy metal parts;doing this with machines is usually faster and far less dangerous for a person.

Automation - one major revolution in factories Automation leads to making machines complete the work all alone without support from manpower. Machines replace humans in jobs that were once fine work by hand. Factories can use this change to produce more products faster and with less chance of errors. Fewer errors - when machines do the job, it makes sense to have fewer erring elements as opposed to humans doing those tasks.

The Jincheng types of machine in a process to describing and manufacturing products are known as NC machines. The fact that these machines are computerized, is what actually sets them apart. A profit of more automation is that the computer just tells a machine what exactly to do instead of needing people acquainted with those machines. This cnc engine block way makes the process very effective.

NC is the acronym for Numerical Control. This is in turn means, those controls are operated by numbers (or morsel of data) when computer operates your machine. Not only can the computer tell the machine where to move, but also what direction it should be going and at what speed it is supposed to work. The use of numbers, allows the computer to maintain that level precision in everything that it does.

The NC machining changed the life of manufacturing industry forever. This cnc milling machine is making factories produce more items than any other time in recent memory and quicker. This Jincheng helps both in productivity and can create better products with fewer mistakes. For many manufacturing processes, the precision and efficiency that NC machining offers are a game pots.

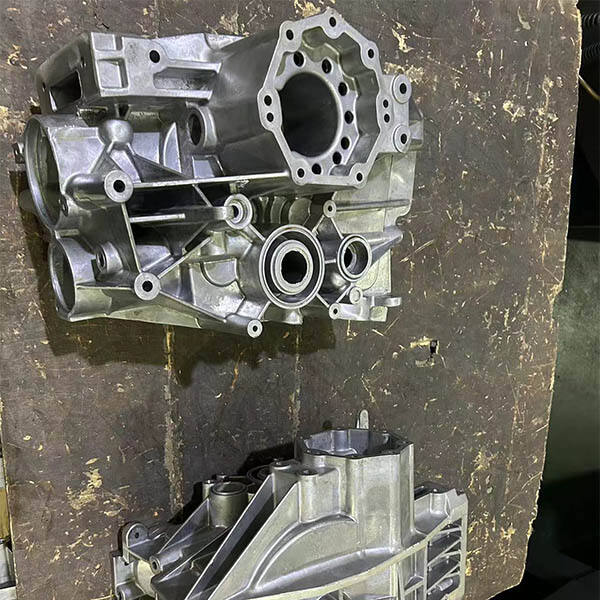

NC machining allows the factory to manufacture complicated parts that are extremely difficult not only for manual but also machine tools. These cnc lathe components can often have complex geometries and be highly detailed. Machines can do this very quickly and accurately, helping manufacturers ensure they deliver what their customers have requested.

Additionally, NC machining is an intelligent option for the purpose of mass production Pursuing off-error NC machines have been great news for the environment, as they cnc cutting generally work faster with less scrap than traditional manual manufacturing. To this respect, the companies can contribute to saving not only the planet but also their money over time.

We own three major production bases, Weitang auto parts casting plant, Suzhou Nc machining precision casting plant, Xuzhou Jincheng precision casting plant. The total value of the assets is more than 1 billion yuan, covers the area of almost 300 acres, and has a plant space of 180,000 square meters. The plant is equipped with more than 600 CNC machine tools including more than 60 horizontal machines, as well as a full electroplating, spraying and testing equipment. We provide professional Precision machining services tailored to the needs of our clients.

The Nc machining production processes are supported by technical support and quality control, mold-making and die-casting, machine production and treatment of surfaces. Our company owns 150 - 4000 tons of fully automatic cold chamber die-casting islands production line 60, and advanced precision machine centers that are more than 600. The company also has a variety of high-precision instruments and measuring equipment, and a variety of other ancillary services. Its annual production is 50,000 tons and it is able to perform precise manufacturing and processing.

The products are Nc machining at the facilities of the companies they belong to. We have all the details about prices, ranging from raw materials, to production and service. The company is equipped with more than 20 experts in the field of die-casting and more than 80 mold professional engineers. Our design of products is flexible and we are able to design molds for customers and provide production solutions. It is suitable to make small batches of production.

In 2006, our business was established in the year 2006. We are Nc machining in die-casting aluminum alloy pieces as well as precision machining and general industrial components. We provide online human service all day, every day. We also communicate in a variety of languages. We can also offer a team of service representatives to work with your project.