Die casting tooling is a technique allows forging metal materials into fine geometries. These ways make the use of special containers, now known as molds, which are made up with high yield strength materials such steel and aluminum. setBackgroundResource. This process is widely used in the manufacturing of a variety of products across different industries too. For example, Jincheng die casting it is applicable in producing automobile parts, electrical components and our everyday kitchen accessories

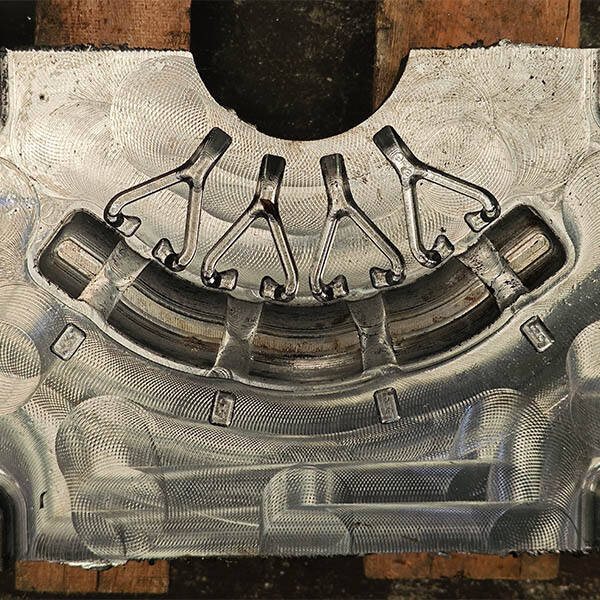

They go through a pretty interesting casting process. From there, it's just pouring molten metal into a mold. The metal is poured into it, and when cools down, freezes in the solid state that we are accustomed to. There is a heavy tooling die casting involved in making such dies. Lastly, we also produce custom molds to give your product a unique shape. In this manner, a custom mould can be prepared and the shape of each item can hence be fabricated in the appropriate form.

The tooling die casting is a crucial part of the process, and without it you may struggle to make anything even resembling high-quality merchandise. This enables them to craft things that could be challenging and even impossible using a different method. This, therefore, allows for the tooling die casting makes to be strong and aesthetically pleasing. In addition, Jincheng engine block they have the ability to customize certain requirements for customers that is a must in this day and age

The new tooling die casting processes are becoming endowing the companies with the higher quality of products as they can make utilisation of them now [ 1 ]. For you one of the best illustrations is a computer-aided design or CAD software. This powerful tool allows manufactures to have exact same 3D parts of both theirs produc It permits them to look for any error or defects in a drawing prior doing the real production. Being able to work things out like this in advance will also save you time and money, by reducing the risk of costly errors.

Yes, it is so beneficial that this Die casting machine helps a ton in not only reducing the downtimes but also cost-effective tooling die castings. This Jincheng engine cylinder block drives excellent and constant products from the manufacturer side as both are required to meet consumer demand. The fact that they can develop something not only solid, but with the aesthetic semblance of a plaster piece has now become an advantage for many organizations.

Tooling die casting has been growing with the technology advancements made over time. One new development here is the use of technology in casting through artificial intelligence (AI), which cylinder block can help to simplify and innovation intelligent life span id=;23814spm1} AI technology can carry out complete casting operation inside foundry in real time It is subject to movement or change until it accurately conforms with particular standards and specifications.

There is going to be a great future in Tooling die casting ahead. The process is continuously experimented with to get better using new technologies and methodologies. But as manufacturers continue to test their limits with tools and die casting, cylinder block in engine it coincides that tooling is now of greater importance than ever in order reach the desired heights.

7 Tooling die casting procedure, technical support, quality inspection, mold making die-casting production, production of machines, processing of surfaces, as well as other facilities. Our company owns 150 - 4000 tons of fully-automated cold chamber die-casting island production line 60, high-precision machine centers that are more than 600. The company also includes ancillary facilities as well as numerous large-scale precision measurement equipment and instruments. They have the capacity of 50,000 tons of aluminum alloy parts for die-casting as well as parts research and development production, as well as precision processing capabilities, to attain the benefits of production on a large scale.

Each product is manufactured at the Tooling die casting of the respective companies. We have all the details about prices, ranging from raw materials to production and services. More than 80 expert mold engineers as well as 20 die-casting experts are available at the company. Our product design is nimble, we can design molds to meet the needs of our customers, and also provide production solutions. It is suitable in small-batch production.

Our company was established in 2006. was founded. We are specialized in die-casting aluminum alloys as well as precision machining and Tooling die casting components. We support 24-hour human online support and communications with minorities in a variety of languages. Additionally, we have the service team to help with the project.

We own three main production centers Weitang auto parts casting plant Suzhou Jincheng precision casting plant Tooling die casting precision casting plant The total value of the assets is more than 1 billion yuan covers the area of almost 300 acres with a total area of 180 000 square meters The company has more than 600 CNC machines including 60 horizontal machining centres with complete electroplating spraying and testing equipment We are committed to providing our customers with high-quality precision machining and customized services