I love creating things with fabric and machines. So lets us know about one of the interesting machine namely VMC Jincheng Communication Parts Products machines. It is also a very chill machine since it find great job and help people making things in the fast way with precision. So here I will tell you all about VMC machine and how it works.

VMC machine- This is a special kind of machine uses to make metal things. VMC: VMC is vertical machining center. This is the reverse chain, it implies that material are tall and standing upright like a skyscraper building. VMC Machine: In VMC machine there is a big flat table where an individual can place the pieces of metal which he or she wants to work. This table is critical as the machine utilizes this to immobilize metal when it does its work.

The spindle is a special tool in VMC machine. The spindle is what rotates and removes metal into the size and shape we desire. It makes for a lot of noise because it spins really fast! While operating a VMC machine, the operator has all access to move spindle up-down-left-right etc. This spindle control allows them to cut the metal very accurately, making sharp and clean cuts.

Making anything using a VMC Jincheng Traditional Auto Parts machine is quite faster and also very well effective. And it is a lot faster than doing the work manually! On the surface of it, VMC machines are simply used to make parts utilizing a cutting tool functioning through an overwhelming and large work program. That means they can produce more products at a lower price which is good for companies.

Many parts can be made simultaneously through VMC Jincheng Products machine which quite an impressive point to note on. A VMC machine is capable of cutting many sides simultaneously in the metal by any user. Being able to work in the two directions speeds up production, and helps people produce more items at a time. This can be incredibly useful for making parts that should have identical sizes and shapes.

Precision engineering is the manufacturing of goods on a micro level, so that they are made specifically to perform with great consistency. The VMC machine has more accurate than the other engineering precision! In return, when a person uses a VMC machine they are able to make very precise cuts. That means they make sure everything will work and be super reliable which is very important in a lot of industries (safety + functionality).

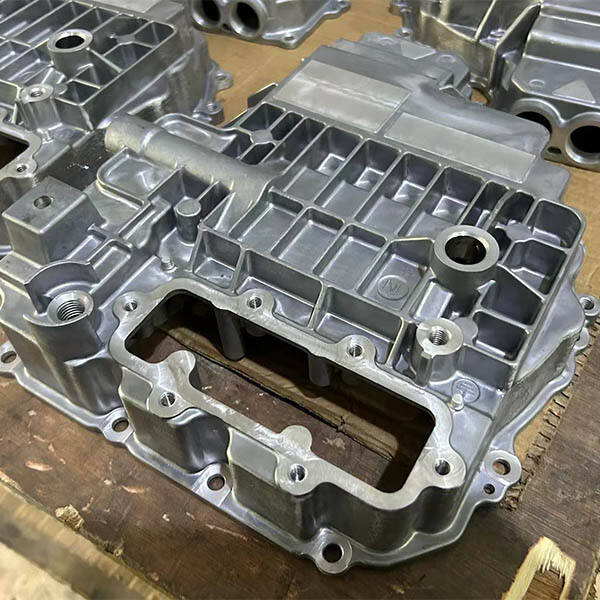

Some need to design something that has a LOT of little, intricate details and complexities. Resolving such issues are especially challenging while fabricating a part of any car or machinery. This can be difficult to accomplish without a VMC machine. The VMC machine allows one to produce shapes and cuts something more intricate than the other kind of creations. It can create a vast array of styles, shapes and sizes so it's very versatile to use in any type of project.

The products are produced by the company's own facilities. We have all the details about prices, ranging from raw materials to production and even services. The company is Vmc machine with more than 20 die-casting industry experts and over 80 mold professional engineers. We can provide molds and production solutions for our customers. Our product design is customizable. It is able to provide the conditions needed to produce small batches.

7 production process, technical support quality control, mold production, die casting production, machine production, surface treatment process, supporting facilities. Our company is equipped with 60 modern precision machining centers and fully automated cold chamber island die-casting production lines ranging between 150 and 4000 tonnes. The company also has dozens of large precision instruments and measuring equipment, as well as various related services. The Vmc machine production of the company is 50,000 tons, and it can perform precision manufacturing and processing.

We have our own 3 major Vmc machine, Weitang auto parts casting plant, Suzhou Jincheng precision casting plant, Xuzhou Jincheng precision casting plant; the total asset size has exceeded 1 billion yuan and covers an area of more than 300 acres, and has a plant space that is 180,000 square meters. The plant has over 600 CNC machines with more than 60 vertical machining centers as well as complete electroplating, spraying and testing equipment. We offer professional precision machining solutions that are customized to our customers.

The Vmc machine was founded by a group of people in 2006. We specialize in traditional automobiles, new energy vehicles, telecommunications photovoltaic energy storage, inverter rail transit, medical aviation, as well as other custom parts made of aluminum alloy, as well as precision machining and general industrial parts. We provide online human service throughout the day, and communicate in minorities languages. We also can provide a team of service representatives to work with your project.