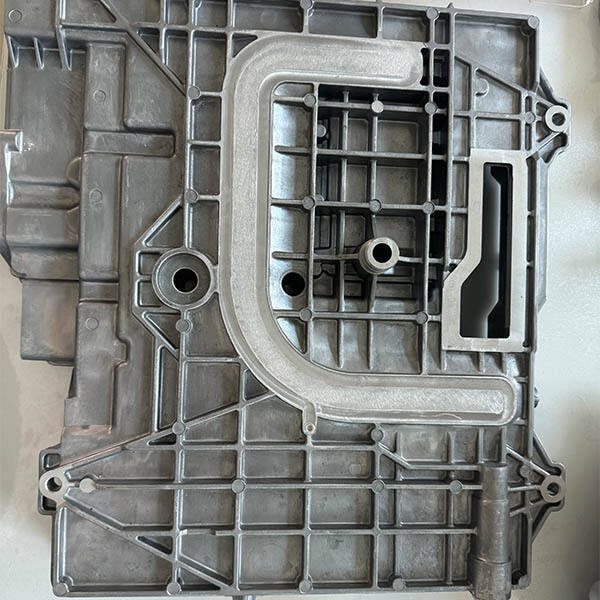

Вы когда-нибудь задумывались, как делают металлические предметы? На самом деле это довольно увлекательно узнать. Jincheng литые под давлением алюминиевые изделия является способом создания металлических объектов, при котором расплавленный металл заливается в форму, где он остывает и застывает (формирует) очертания отливки. Использование формы в этом процессе называется штамповой формой. Уникальная форма создаётся при производстве изделий из алюминия, чтобы они обладали максимальной детализацией и прочностью. Это важно, поскольку это влияет как на внешний вид, так и на характеристики продукта.

После дизайна пришло время создать саму форму. Она производится качественно, обычно с использованием фрезерных станков и с помощью квалифицированных рабочих на заключительном этапе производства. Сначала делается грубый заготовка в форме ремня из блока стали. Этот грубый контур является только отправной точкой. Затем заготовку обрабатывают до получения конечной формы с помощью другого станка. Процесс настолько точный, что Джинчэнг литье алюминия под давлением вкладывает средства в создание формы, обеспечивая достаточное качество и детализацию.

Форма для горячекамерного литья под давлением — это другой вид квалифицированной формы. Такая форма主要用于 metals, плавящихся при низких температурах, таких как цинк или магний. Её называют горячей камерой, потому что расплавленный металл, помещаемый в этот резервуар, сохраняет подходящую температуру до момента заливки в форму. Это помогает убедиться, что металл равномерно течет в форму.

Если вы хотите ускорить производство, вместо одной пузырьковой формы используйте многопузырьковую. Эта форма состоит из нескольких полостей; части обычно производятся одновременно. Джинченг поставщики литья под давлением из алюминия это сэкономит много времени и материалов, но результаты будут точными. Сделайте несколько за один раз. Хотите умножить свои комплименты для себя - даже больше, чем просто удвоить их, как в выпечке партии печенья против одного печенья.)

Горячая форма - еще один способ увеличить скорость производства. Для этого формы не нужно использовать каналы, которые направляют жидкий металл в места, где будут сформированы детали. Кроме того, отходы из плесеньки выводятся быстрее, поскольку не остается никаких отходов. Это замечательно, потому что металл будет меньше отходов, и за меньшее время можно будет произвести еще больше продуктов.

Форма должна быть тщательно изготовлена и многократно проверена на наличие любых проблем для поддержания этой точности. В регулярные промежутки времени рабочие должны проверять, есть ли какие-либо дефекты или искажения в форме. Все, что требует исправления, должно быть исправлено, чтобы качество каждого конечного продукта оставалось на высоте. Фокус на таких деталях создает основу для потока производства.

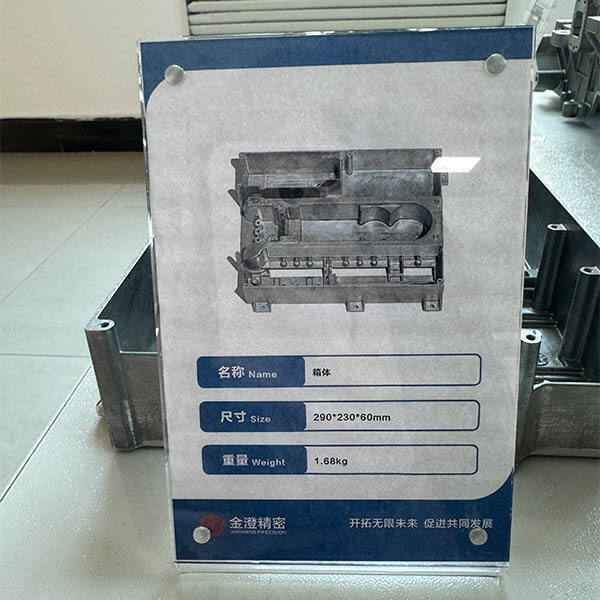

У нас есть свои 3 крупных завода по литью под давлением алюминиевых форм: завод автокомпонентов Weitang, завод точного литья Suzhou Jincheng и завод точного литья Xuzhou Jincheng. Общий размер активов превышает 1 миллиард юаней, занимая площадь более 300 му, с производственными помещениями общей площадью 180 000 квадратных метров. На заводе установлено более 600 ЧПУ-станков, включая более 60 вертикальных обрабатывающих центров, а также полный комплект оборудования для электрохимической обработки, окраски и испытаний. Мы предлагаем профессиональные решения для точной мехanoобработки, адаптированные под потребности наших клиентов.

Продукция изготавливается на собственных мощностях компании. От закупки сырья до последующего производства и обработки мы предоставляем подробные сведения о ценах. В компании работает более 80 квалифицированных инженеров-модельщиков, а также 20 специалистов по литью под давлением. Наш дизайн продуктов гибкий, мы можем разрабатывать формы для удовлетворения потребностей наших клиентов, а также предлагать формы для литья под давлением из алюминия. Это позволяет производить малые партии продукции.

Наша компания начала заниматься литьем под давлением из алюминия в 2006 году, специализируясь на традиционных автомобилях, инновационных энергетических транспортных средствах, телекоммуникационных инверторах, фотоэлектрическом накоплении энергии, железнодорожных перевозках, медицинской авиации, а также другими заказными компонентами из алюминиевых сплавов, точной механической обработкой и общепромышленными деталями. Мы обеспечиваем круглосуточную техническую поддержку и связь на редких языках. Также мы можем предложить команду сервиса для работы над проектом.

Процессы производства форм для литья под давлением из алюминия поддерживаются техническим обслуживанием и контролем качества, изготовлением форм и литьем под давлением, производством машин и обработкой поверхностей. Наша компания располагает 60 полностью автоматическими линиями производства островков холодной камеры для литья под давлением мощностью от 150 до 4000 тонн, а также более 600 современными точными центрами обработки. Компания также имеет различные высокоточные приборы и измерительное оборудование, а также другие вспомогательные услуги. Ежегодный объем производства составляет 50 000 тонн, и она способна выполнять точное производство и обработку.