Века назад (долго до появления устройств числового программного управления) люди изготавливали блоки двигателей, заливая расплавленный металл в форму и давая ему остыть. Этот процесс был длительным и не очень точным. Дефектная отливка могла означать неправильную посадку блока двигателя или, что хуже, проблемы с автомобилем. Теперь блоки двигателей изготавливаются с помощью этого волшебного технологического решения — ЧПУ, и это все изменило.

ЧПУ — Числовое Программное Управление, то есть компьютер управляет машинами, которые выравнивают и отливают блоки двигателей. Цзинчэн блок цилиндров является отличным инструментом для автоматизации процессов без участия людей в ручном труде. На сегодняшний день блок цилиндров можно произвести всего за несколько дней с помощью этой технологии, тогда как раньше на это уходило недели! Наши автомобили становятся всё сложнее с годами, и это приближает производителей машин к возможности делать всё быстрее.

Производство блока двигателя по-старому, до появления технологии ЧПУ было задачей и половиной. Это должно было быть сделано рабочими с помощью клещей и молельных молотков, для этого требовалось много навыков и это, безусловно, заняло некоторое время! Джинченг алюминиевый блок двигателя он сделал их очень тщательными во всем. В отличие от этого, с помощью ЦНК можно работать намного быстрее, что удобно как для тех, кто обрабатывает металл, так и для тех, кто обрабатывает скрепленные элементы.

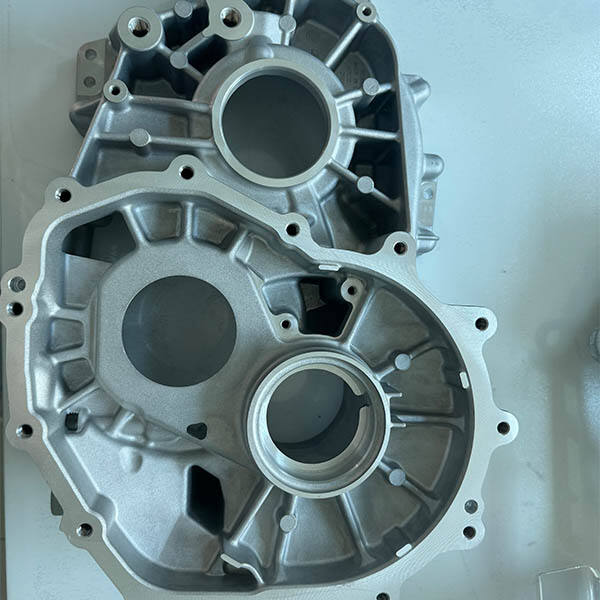

Дизайнеры используют компьютер, чтобы сначала создать модель блока двигателя. Эта модель ясно иллюстрирует, как должен выглядеть блок двигателя. Затем компьютер передает эту модель на станку с ЧПУ. Программа читается с помощью станка с ЧПУ, которая затем использует микрокорректировки для резки и контура металла, чтобы он напоминал блок двигателя. Это позволяет сэкономить много времени и помогает в производстве более точных компонентов, которые имеют решающее значение для качества автомобилей.

Оптимизация процесса производства блоков цилиндров с помощью технологии CNC

Использование технологии ЧПУ изменило процесс производства блоков цилиндров, и это стало значительным достижением в автомобильной промышленности. Однако оно будет только улучшаться! Не стоит сомневаться, что инженеры постоянно работают над новыми способами улучшения конструкции блоков цилиндров в будущем. Захватывающе то, что автомобили могут становиться лучше со временем благодаря Джинчэнгу. двигательный блок автомобиля .

Блоки цилиндров также могут выиграть от других инноваций, таких как использование новых материалов. Пока что блоки цилиндров в основном делаются из чугуна или алюминия — прочных, хотя относительно тяжелых материалов. Они также будут стоить дороже (хотя в будущем их можно будет делать из более легкого углеродного волокна). Это снизит вес транспортных средств и поможет им потреблять меньше топлива, что полезно для окружающей среды.

Они также могут обратить внимание на обувь, напечатанную на 3D-принтере. 3D-печать — это создание физического объекта из цифровых файлов, которые манипулируются в трехмерном пространстве; можно создать что-то практически из любого материала или среды. Возможно, когда-нибудь мы сможем создавать блоки двигателей таким образом. Это сэкономило бы гораздо больше времени и даже было бы идеально. Представьте, как здорово было бы разработать и затем напечатать блок двигателя за считанные минуты — вместо того, чтобы вырезать его из куска стали.

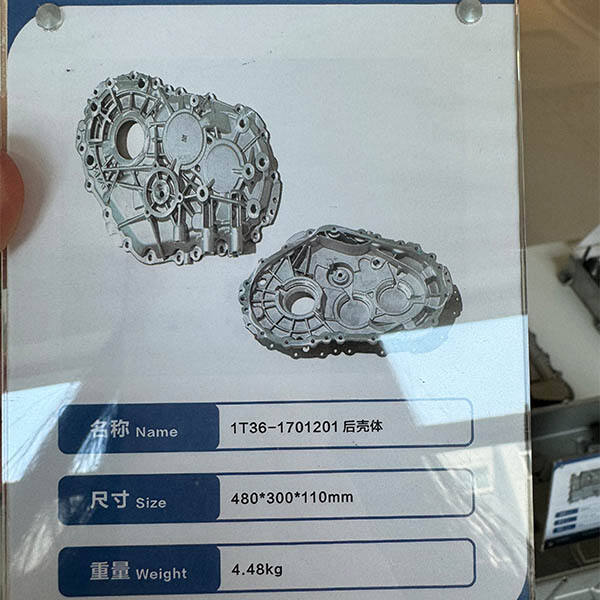

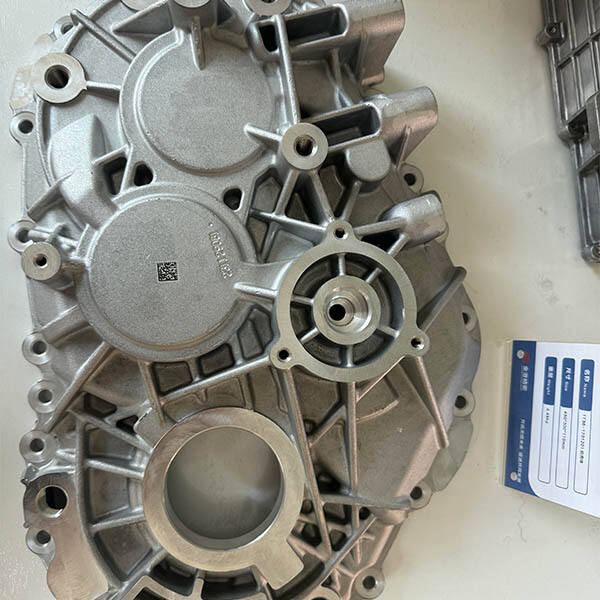

Гильза двигателя CNC с наших производственных площадок: завод литья автозапчастей Вейтан, завод точного литья Сучжоу Джинчэн, завод точного литья Сючжоу Джинчэн. Общий объем активов превышает 1 миллиард юаней и занимает 300 мук. Площадь завода составляет 180 000 квадратных метров. Компания располагает более чем 600 станками с ЧПУ и 60 горизонтальными обрабатывающими центрами, а также полным набором оборудования для электрохимической обработки и испытаний покрасочных установок. Мы стремимся обеспечить клиентов профессиональной точной мехanoобработкой и услугами по индивидуальному проектированию.

7 производственный процесс, техническая поддержка, контроль качества, производство форм, производство штамповки под давлением, машинное производство, обработка поверхностей, а также другие объекты. Наша компания оснащена 60 полностью автоматизированными линиями производства штамповки под давлением с холодной камерой мощностью от 150 до 4000 тонн, и более 600 современных точных станков. Кроме того, в компанию входят вспомогательные объекты, а также многочисленные крупные устройства высокоточной измерительной техники Cnc для блоков цилиндров, с годовым производством 50 000 тонн алюминиевых сплавов для штамповки под давлением, а также разработкой, производством и высокоточной обработкой деталей для обеспечения крупномасштабного производства.

Продукция изготавливается на собственных мощностях компании. От закупки сырья до последующего производства и обработки мы предоставляем подробные сведения о ценах. В распоряжении фирмы более 80 квалифицированных инженеров-модельщиков и 20 специалистов по литью под давлением. Наш дизайн продуктов гибкий, мы можем разрабатывать формы для удовлетворения потребностей наших клиентов, а также предлагать блоки цилиндров CNC. Мы можем обеспечить условия для малых партий производства.

Наша компания была основана в 2006 году. Мы специализируемся на точной механообработке алюминиевых сплавов для блоков цилиндров CNC, а также на общепромышленных деталях. Мы предлагаем круглосуточное онлайн-обслуживание и общение на языках национальных меньшинств. Мы также можем предоставить команду экспертов для помощи в конкретном проекте.