Итак, вы осведомлены о том, что литьевой алюминий — это уникальный материал? Он идеально подходит для создания легких и крученно-прочных изделий. Это также говорит о том, насколько он компактен для переноски и частой разборки. Эти качества делают Джинчэн литые под давлением алюминиевые изделия серьезным конкурентом, именно поэтому он так отлично создает формы при литье других материалов.

Формы являются специальными инструментами, которые позволяют нам иметь разнообразие форм. Их можно использовать для производства практически всего — забавных гаджетов, важных деталей машин и многого другого. Одним из ключевых элементов для формования является наличие хорошего материала. Высококачественные материалы также продлевают срок службы форм и обеспечивают их правильную работу, тогда они могут эффективно выполнять свою задачу!

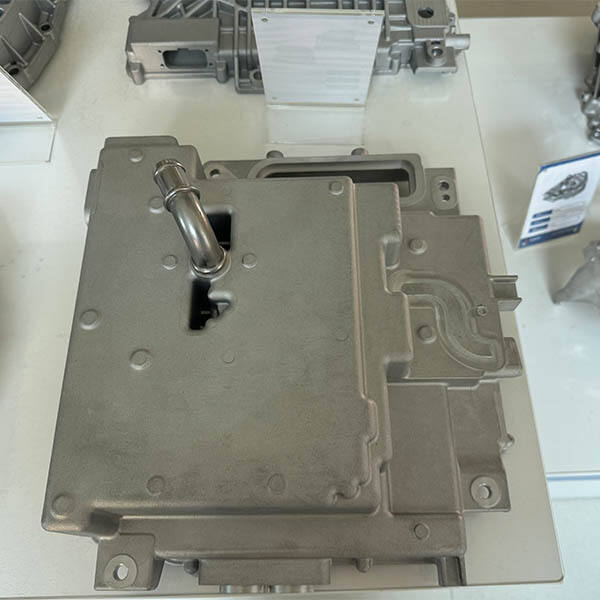

Здесь мы делимся с вами информацией о том, как работает литье алюминия при создании форм. Литье алюминия - это процесс, при котором горячий жидкий металл заливается в форму. И это делает его чрезвычайно прочным после того, как металл охлаждается. Это компания Jincheng литье алюминия под давлением делает алюминий более прочным, а затем помогает вам быстро проектировать формы.

Литой алюминий легкий и прочный, что дополнительно обеспечивает универсальность. Вы можете делать забавные игрушки, возможные детали машин, а также элементы внутри самолетов или автомобилей! Эти формы можно переиспользовать, что является еще одним очевидным преимуществом литья алюминия! Это избавит вас от необходимости создавать новые формы каждый раз, когда это необходимо.

Литой алюминий идеально подходит для одновременного производства многих форм. Подумайте о всех игрушках или деталях, которые вы могли бы произвести за очень короткое время. Эта технология Джинчэнг не только экономит уйму времени, но и позволяет сэкономить деньги. Кроме того, формы можно использовать много раз, что означает, что вам не придется покупать новые, когда вы красите что-то обычного веса. поставщики литья под давлением из алюминия это не только экономит огромное количество времени, но и позволяет сэкономить деньги. Помимо этого, формы можно использовать множество раз, что означает, что вам не нужно будет снова покупать новые при окрашивании предметов обычного веса.

Одна типичная проблема — это точное получение раскладки формы. Если конструкция детали не оптимальна, форма может работать плохо, либо вы рискуете получить конечный продукт, который выглядит не так, как должен. Планирование дизайна форм: это, вероятно, самый важный способ преодолеть этот вызов. Как только у вас будут готовы ваши дизайны, тестирование их на практике поможет избежать ошибок в будущем.

Другая проблема заключается в том, что его необходимо хорошо смазывать до самой формы. Смазка критически важна для того, чтобы материалы выскальзывали на сотые доли миллиметра легче из формы. Если смазки недостаточно, то могут появиться области, где пластик может застрять и в конечном итоге сломать форму. ПРОФИ-СОВЕТ: Корректная регулировка платформы (в контексте данной статьи) помогает избежать скрипов и шума во время печати для качественного равномерного прилипания; используйте хорошие смазочные материалы в зазорах + очищайте свою форму.

7 этапов производственного процесса: техническая поддержка, контроль качества, производство форм, производство штамповки под давлением, механическое производство, процесс обработки поверхности, вспомогательные设施. Наша компания оснащена 60 современными центрами точной механообработки и полностью автоматизированными линиями производства штамповки под давлением в холодной камере мощностью от 150 до 4000 тонн. Компания также располагает десятками крупных точных приборов и измерительного оборудования, а также различными связанными услугами. Производство штамповочных алюминиевых форм составляет 50 000 тонн, и мы можем выполнять высокоточное изготовление и обработку.

В 2006 году наша компания была основана. Мы специализируемся на производстве компонентов из алюминиевого сплава методом штамповки под давлением с точной механообработкой, а также на общепромышленных деталях. Мы предоставляем онлайн-поддержку для штамповки алюминиевых форм и общаемся на языках национальных меньшинств. Мы также можем предложить вам команду обслуживания для вашего проекта.

У нас есть три основных производственных центра: завод по литью автозапчастей Вейтан, завод точного литья Сучжоу Джинчэнг и завод точного литья под давлением из алюминиевых форм. Общая стоимость активов превышает 1 миллиард юаней, занимаемая площадь составляет почти 300 мǔ с общей площадью 180 000 квадратных метров. Компания располагает более чем 600 ЧПУ-станками, включая 60 горизонтальных обрабатывающих центров, а также полным набором оборудования для электрохимической обработки, окраски и испытаний. Мы стремимся предоставлять нашим клиентам высококачественную мехanoобработку и индивидуальные услуги.

Товары производятся на собственных заводах. Мы предоставляем всю информацию о ценах, от сырья до производства и услуг. В компании работают более специалистов по формам для литья под давлением из алюминия и 20 экспертов в области литья под давлением. Мы можем поставлять формы, а также решения для производства нашим клиентам. Наш дизайн продукции гибкий, что позволяет осуществлять выпуск небольших партий.