Aluminium is a very versatile metal used in many different industries for applications that include cars, airplanes and buildings. An aluminium billet block (one of the most common shapes aluminum is found),

A look into the manufacturing of aluminum billet blocks

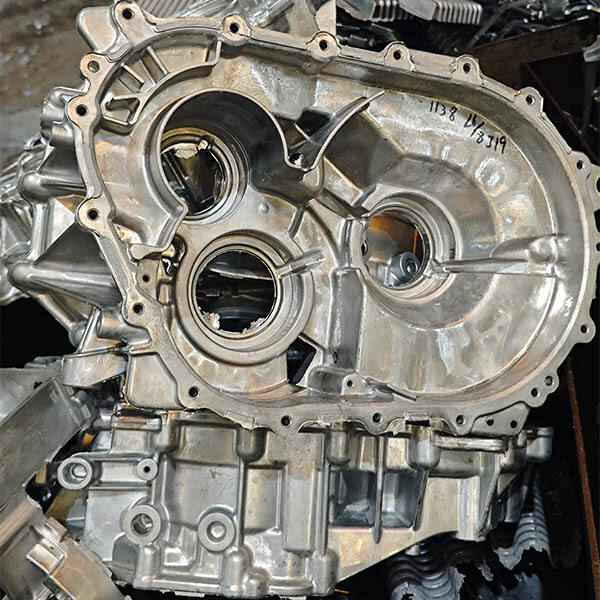

An aluminum billet block casting begins life as a raw, molten bath of high-grade/aircraft-quality A-356-alloy cast aluminium. Then try again and then the liquid is poured into a long rectangular shaped mould called billet. When the molten aluminum cools, it is removed from the mold and cut into blocks.

Lightweight, easy to work with and strong as hell; aluminum billet blocks are used in a wide range of industries. For example, in the production of vehicle parts such as engine blocks and wheels. They are essential in the construction industry as well; where they go into making window frames and doorframes.

The Benefits Of Using High-Grade Aluminium Billet Blocks in Production

The use of premium-quality aluminium billet blocks during the process offers many advantages. These blocks are notably versatile in terms of feedstocks; many can tolerate significant loading and unloading, with longer life spans. Their strength to weight ratio makes them the ultimate traveler since they are incredibly strong yet also very light, not adding unwanted stress on your finished product. The manipulative leniency also makes it simpler for manufacturers to mould them into definite shapes.

Aluminum billet blocks are among the best in class used by aerospace manufacturers, since they save weight, provide strength and durability as well corrosion resistance. Flight is too demanding a test to do without these features, after all.

When it comes to the modern engineering practices, billet blocks also have a huge influence on them as they are used in producing various goods from vehicles and aircrafts along with anything that we see around us till structures or household items. Their unique combination of high strength, excellent toughness and low weight makes these materials great choices for use in a wide variety of engineering applications. Moreover, for its economy and high availability of them this became a favourite choice among manufacturers globally.

Aluminum billet blocks provide critical building materials for various trades and is used in sectors due to their toughness, durability, and lightweight properties. The availability of such products in all settings, and cost effecitiveness further reinforce their high standing among global industry provocateurs keeping the necessity for these prompts inevitable engineering practices even today.

7 production process, technical support, quality inspection, mold making die casting production, machine production surface treatment, and supporting facilities. Our company has aluminium billet block machining centers, completely automatic cold chamber island die-casting production lines ranging from 150 - 4000 tons. The company also has various ancillary facilities and numerous large-scale precision measurement equipment and instruments, with an annual production of 50,000 tons of aluminum alloy die casting parts and parts research and development production and precision processing capabilities to get the impact of large-scale production.

The products are made in the factories of the respective companies. We provide all the information on prices, from raw materials to production and even services. More than 80 mold engineers and aluminium billet block die-casting experts are in the company. Our product design is flexible and we are able to design molds for customers and provide production solutions. It can be used for small-batch production.

We own three major production bases, Weitang auto parts casting plant, Suzhou aluminium billet block precision casting plant, Xuzhou Jincheng precision casting plant. The total value of the assets is more than 1 billion yuan, covers the area of almost 300 acres, and has a plant space of 180,000 square meters. The plant is equipped with more than 600 CNC machine tools including more than 60 horizontal machines, as well as a full electroplating, spraying and testing equipment. We provide professional Precision machining services tailored to the needs of our clients.

Our company was aluminium billet block in 2006, specializing in traditional cars, innovative energy vehicles, telecommunications inverter, photovoltaic energy storage rail transit, medical aviation, as well as other custom aluminum alloy die-casting components and precision machining and general industrial components. We support 24-hour human online support and communications in minority languages. We can also provide a service team to connect with a project.