So when we lacked a material sturdy enough, yet light for the design of our bridges is where Jincheng aluminium casting manufacturers would come in. You may have encountered it in planet flying high above or in the sprinkle tumblers, which serve us cold soda pop on a wicked hot day. Aluminium casting is the process used for preparing many of these items. The aluminium casting process is an intriguing process which helps in making the products around us.

Alloy casting, an essential aid in the process of crafting from strong and dependable aluminium into molten substance by expert professionals. After the aluminum is molten, they pour it into a mould. A mold works like a special holder which shapes the melted aluminium sauce. Eventually, the aluminum cools down and hardens into the mold shape. This is integral as it requires trained people to produce quality product which can be used safely.

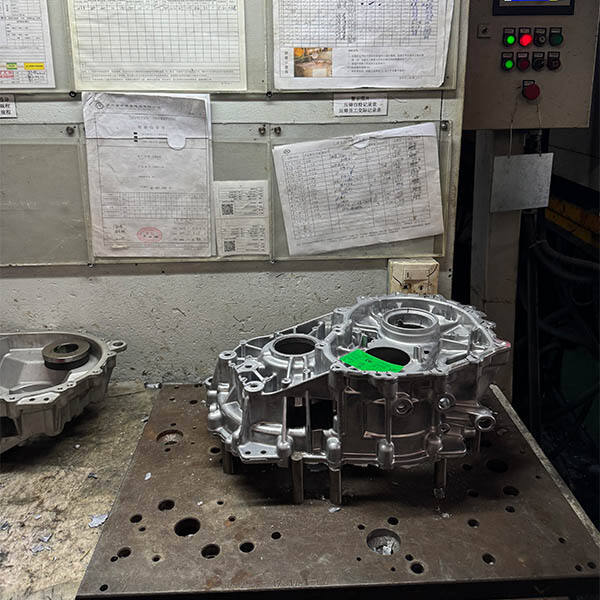

Aluminum products manufacturers employ special tools and equipment such as huge furnaces to heat the metal at high temperatures or molds that form it into a variety of shapes. These Jincheng aluminium casting manufacturers have an acute eye for detail when it comes to casting and everything must be pure perfect. In a way it can be considered as high quality work making sure every product is built well which will just works fine.

Select High-Quality Materials A crucial component in finding creating quality die casting products is using high-quality materials. Manufacturers use only the best aluminium and they will then need to take great care in how it is manufactured or believe you me there could be people who are going, damn this manufacturer ain't all that good he sold us some poorly made frames. They seek to produce products that are safe and for which people can use in complete confidence.

Jincheng aluminium casting manufacturers spend a lot of their time researching and developing new techniques to make aluminum die casting products process as well, so that they can continue making better versions of what has caught the imagination. This research helps them discovering more productive ways and ideas how they can make a best-in-class products for their customers. In fact they are always seeking ways to step their game up.

Precision casting this is one of the newer techniques. This die casting process is an incredible process that involves wax molds coated with a liquid medium, which then solidifies to make of the outer shell. The wax is then melted away, allowing liquid aluminium to flow into the appropriately-shaped void left by the waxy model. As a result, Jincheng aluminium casting manufacturers can create highly-detailed and precise products with extremely complex shapes.

The Jincheng aluminium casting manufacturers have the ability to print parts for machines that are made specifically for those unique pieces of equipment. And the materials available for custom 3D printed parts may give them strength and longer life over their counterparts in different materials–something that is valuable to aluminium die castings machines which work full time every day of each year.

The Aluminium casting manufacturers production processes are supported by technical support and quality control, mold-making and die-casting, machine production and treatment of surfaces. Our company owns 150 - 4000 tons of fully automatic cold chamber die-casting islands production line 60, and advanced precision machine centers that are more than 600. The company also has a variety of high-precision instruments and measuring equipment, and a variety of other ancillary services. Its annual production is 50,000 tons and it is able to perform precise manufacturing and processing.

We have our own 3 Aluminium casting manufacturers production facilities, Weitang auto parts casting plant, Suzhou Jincheng precision casting plant, Xuzhou Jincheng precision casting plant; the total assets have surpassed 1 billion yuan and covers the area of almost 300 acres and a plant area of 180,000 square meters. The company is equipped with more than 600 CNC machines with more than 60 vertical machining centers and complete electroplating and spraying equipment. We're committed to providing customers with professional precision machining, customized services.

Our company was established in 2006. was founded. We specialize in Aluminium casting manufacturers aluminum alloy components in precision machining as well as general industrial parts. We offer 24 hours of human-to-human service online and also communication in languages of minority. We can also provide an expert service team to assist with a particular project.

The goods are made in their own factories. We provide all the information regarding prices, from raw materials through production and services. More than Aluminium casting manufacturers expert mold engineers and 20 experts in die casting are on hand at the firm. We can supply molds as well as production solutions for our customers. Our product design is flexible. It can provide conditions to produce small batches.