Aluminum is a metal that is actually very important in the use of most appliances we need daily. It is all around us you just might not realize. Aluminum and other metals are sometimes melted down, recast into different shape. The process is known as casting and the melted metal used in this is referred to as casting ingots.

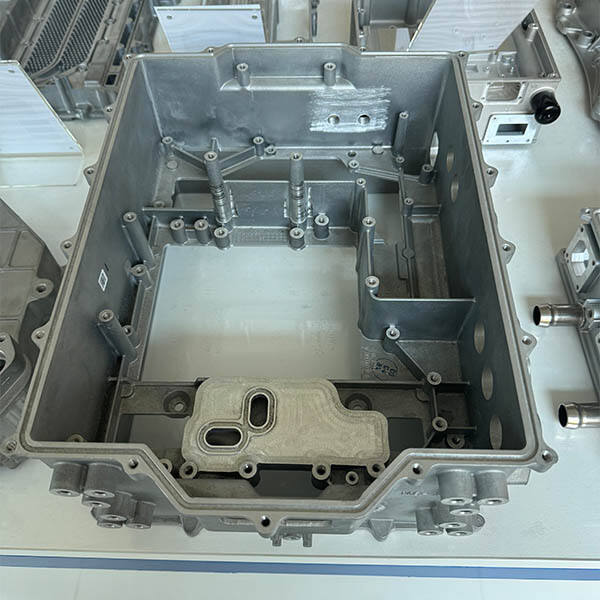

What a great thing the aluminum casting process is. Melt aluminum to a liquid first. It's like how ice becomes water when it is exposed to heat. After melting it, the aluminum becomes a liquid and is poured into a mold. A mold is something has a shape like the thing we want to make but much bigger, think of it as cookie cutter. The Jincheng aluminium die castings starts to cool and harden it begins to take the form of your cube. Think of it like pouring melted chocolate to form an interesting shape and then allowing it set which is what happens with aluminum.

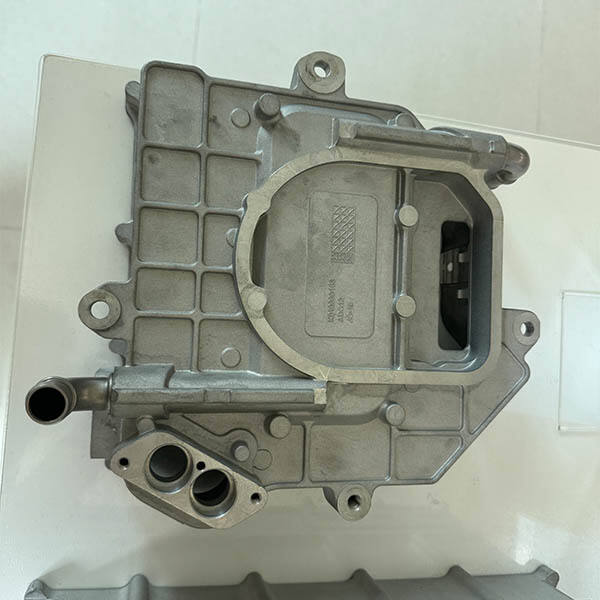

Why Is Aluminum Casting So Awesome. You able to use it for making this and that.. Aluminum is both strong and lightweight, making it ideal for use in a plethora of products. It is used in a fast-moving car, high-flying aircraft or water sailing boat. From cooking utensils to soda cans and even aluminum foil - we use it every day. When you open a soda can next time, just remember that you were able to do this thanks to Jincheng aluminum die casting suppliers.

CASTING ALUMINIUM = ANYTIME GOOD FOR ECONOMICS + ENVIRONMENT... One other positive to aluminum is that it can be recycled over and over again. Once we have finished using aluminum products, this can be recycled and melted down to create new items. This is cost savings and environmentally friendly less waste. Jincheng aluminum die casting is also very light which means it can help to make cars and planes use less fuel, saving everyone money.

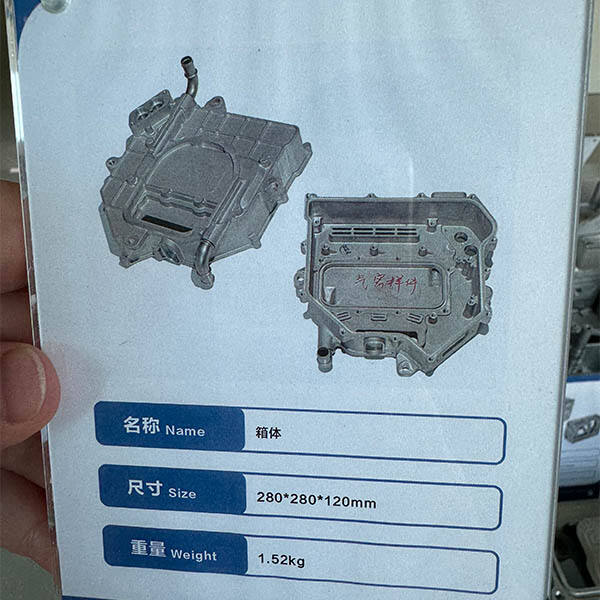

Correct Aluminum Casting Ingot for your project is essential. Alloys As you will be learning in the spring semester, aluminium comes in different 'fits for purpose' al lots. Alloys The vast majority of aluminum wheels are cast out of an alloy either using a relatively low pressure method or poured with higher pressure. Making a Choice for Base Metal The right choice of alloy can make or mar your project. For instance, if you are fabricating anything to be weight bearing and extremely strong then need use a tougher grade of Aluminium.

This stuff is fun - reading up on the various types of aluminum alloys and what makes each one unique. Aluminum (there are many different types of aluminum alloys, such as 6061 or 7075 and A356.) They all have their unique features that make them more suitable for specific projects. For example, 7075 aluminum is extremely strong and frequently found in aircraft whereas A356-aluminum is less rigid and commonly used for the construction of automobiles. The type of the aluminum can help you to make a fantastic product as well.

7 production process, technical support, quality inspection, mold making die-casting production, production of machines Aluminum casting ingots, and supporting facilities. Our company boasts 150 - 4000 tonnes of fully automated cold chamber die-casting island production line 60, and advanced precision machining centers more than 600. The company also owns a plethora of high-precision measuring instruments and equipment and a variety of ancillary services. The annual production of the company is 50,000 tons and it is able to perform precise processing and production.

We own three main production centers Weitang auto parts casting plant Suzhou Jincheng precision casting plant Aluminum casting ingots precision casting plant The total value of the assets is more than 1 billion yuan covers the area of almost 300 acres with a total area of 180 000 square meters The company has more than 600 CNC machines including 60 horizontal machining centres with complete electroplating spraying and testing equipment We are committed to providing our customers with high-quality precision machining and customized services

In 2006, our company was founded. We are specialized in die-casting aluminum alloy components in precision machining as well as general industrial parts. We provide online human service Aluminum casting ingots and communicate in minorities languages. We also can provide a service team for your project.

The products are made in the factories of the respective companies. We provide all the information on prices, from raw materials to production and even services. More than 80 mold engineers and Aluminum casting ingots die-casting experts are in the company. Our product design is flexible and we are able to design molds for customers and provide production solutions. It can be used for small-batch production.