Ever thought about how a toy car, kitchen tools and even airplane parts are manufactured? It's really interesting! Aluminum Die Casting. Here is a way to produce them, this process being Jincheng aluminium die castings. In other words, it created a mold from aluminum - a very tough and light metal.

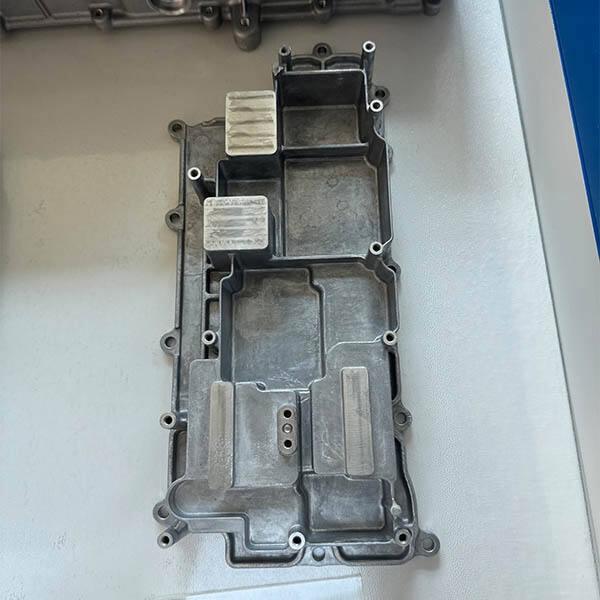

What is an Aluminum Die Casting Mold? Think of it as a kind of metal cookie cutter you might use in the kitchen. A cookie cutter is an object that you push down into dough to create fun shapes. If a baker were using it, instead of dough, he will place the already melted aluminum here and not on hot plate or any other thing like that. This molten aluminum is of course very hot, and once it cools down, what was liquid now solidifies into the shape. These Jincheng aluminum die casting molds are capable of producing products that not only bear excellent toughness but also have a very lighter weight and smooth finish.

There are several advantages of using Aluminum die casting which make it an attractive option for producing product. The main reason for that is it allow us to make stuff really fast. Aluminum is a material that has such low melting temperatures it can be easily shaped into a mold quite quickly. So, this works particularly well when you have to make a large number of items quickly. This is part of why it's relatively cheap, being light weight and high strength. This is crucial for aircraft parts, where weight and balance are everything. Finally, Jincheng aluminum die casting suppliers also has aesthetic purposes and it makes things look pretty due to its clean finish. This smoothness can also go a very long way towards how neat and tidy your product look to the eye of the customer.

Aluminum die cast molds also have significant advantages which explains why they are quite popular in the process of manufacturing. They are also reusable many times which is a huge plus. A mold is a one-time set-up, and then it can run thousands of parts without replacement. This saves time and money. This is also advantageous because these molds allow for much additional detail. Consequently, the components crafted using these molds will be identical for every part produced by them but this property is great when it comes to quality testing. That is to say that if you buy a toy car or any kitchen tools, it must be made in the exact same way.

So where does the future of aluminum die casting lie? Even new methods on how to produce molds rapidly and accurately are being developed. They are even searching for the new materials to use in aluminum die casting and reap benefits from the same. We can now create more wonderful things from aluminum with those new ideas and improvements This effectively means we will see new, groundbreaking products that may improve our lives and how we all do business.

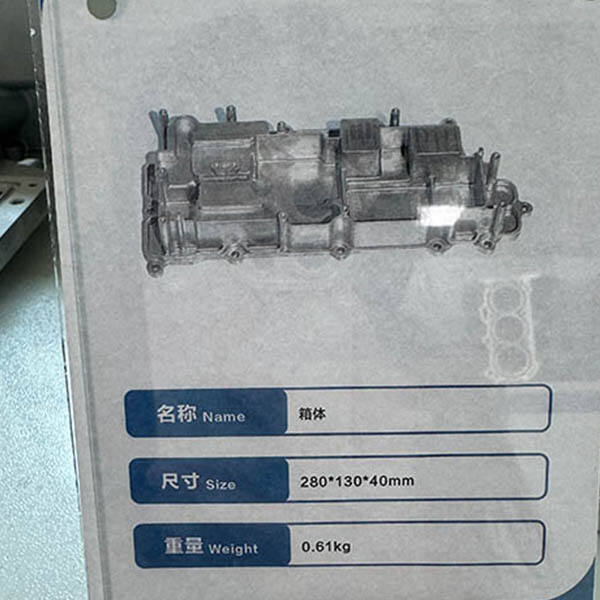

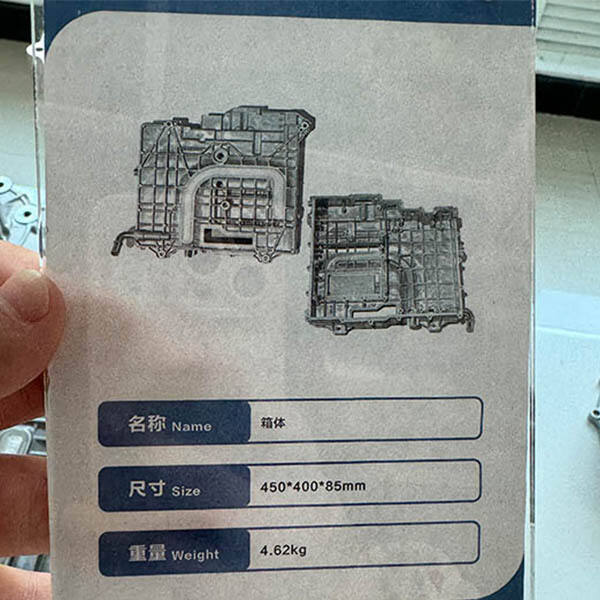

Our company was founded in 2006, and is specialized in Aluminum die cast mold, modern technology vehicles for energy, telecommunications, photovoltaic energy storage, inverter, medical, rail aviation, and other custom aluminum alloy die-casting components and precision machining as well as general industrial parts. We offer 24 hours of human-to-human online service as well as communication in minor languages. We can also provide representatives from our service department to help you with your project.

The seven production processes include the following: technical support, quality control, mold-making die-casting, machine production and surface treatment. Our company Aluminum die cast mold 150 - 4000 tons of fully automatic cold chamber die-casting production lines 60, and advanced precision CNC machining centers with more than 600. The company also owns a plethora of high-precision instruments and measuring equipment, as well as various additional services. Its annual production is 50,000 tons and it's able to do precision processing and production.

The products are made in the factories of the respective companies. We provide all the information on prices, from raw materials to production and even services. More than 80 mold engineers and Aluminum die cast mold die-casting experts are in the company. Our product design is flexible and we are able to design molds for customers and provide production solutions. It can be used for small-batch production.

We have our own 3 important production facilities, Weitang auto parts casting plant, Suzhou Jincheng Aluminum die cast mold, Xuzhou Jincheng precision casting plant; the total value of the assets is more than 1 billion yuan, covers an area of nearly 300 acres, and has a plant space that is 180,000 square meters. The company has over 600 CNC machines with more than 60 vertical CNC machining centers, and a complete spraying, electroplating testing equipment. We offer professional precision machining services that are tailored for our clients.