Hello friends. Aluminum Die Casting Molds Know How You ever heard of a mold? A mold is a specific form or model we can use to produce something. As a simple example when you bake cupcakes, the basic mould is to shape your batter into yummy cupcake. In the same way, Jincheng aluminium die castings is used to make a myriad of items such as vehicle parts, toys and also critical components for planes. Isn’t that interesting?

The biggest advantages of aluminum die casting molds is that their durability and strength. They are definitely reusable which means they will not break or lose their shape when you use them numerous times to produce other components. The molds are also incredibly precise which make corresponding parts molded out of these materials will fit perfectly with each other. This is more important because it will guarantee that everything works well when all these parts come together.

One other great thing about aluminum die casting molds is that they are quick and extremely economical to use. Which implies you possibly can produce plenty of parts in a brief time and doesn't price so much cash. The aluminum molds used to make these are convenient and easy enough for molten metal casting into complex shapes facilitating the crafting smoother as well as faster.

So, now we have a little knowledge about the aluminum die casting molds and why they are so appreciating; let's jump to one of our other questions mentioned earlier, that is how these types of mold are made. At first an engineer, who is someone that designs things, makes a plan or design for the part they want to make. The Jincheng aluminum die casting is then made based on this design. After the mold cools down, aluminum is poured into it to create a casting. When it does, the aluminum cools and hardens to make The Part. Then, gently removed from the mold by hand and any surplus material will be cut away cleanly so it looks nice.

Aluminum die casting molds are applied in a variety of industries, industrial sectors where goods or services are developed. Automobile industry, where most of the cars are made is one such places from which we will get these molds found for you. Jincheng aluminum die casting suppliers are used in the creation of car parts such as engines, wheels, and various other critical components. Moreover, such molds are used to make domestic appliances as refrigerators, washing machine and other daily usage machines. Toys like model cars and action figures are used from aluminum die casting molds. It is interesting, how much they are used in so many things?

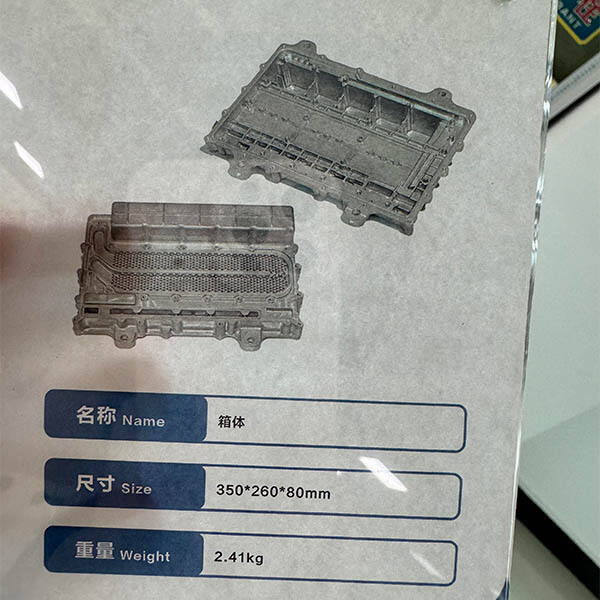

Whether you are working on a project that requires aluminum die casting mold, it is imperative to choose the one as per your requirement. You need to consider several aspects, like the size and shape of part you want to fabricate, how many number of parts has been require for production run as well as cost incurring towards making mould. It is also wise to select a firm that has actually had experience in manufacturing good molds. This way, they can give you good results in your project.

Aluminum die casting molds are widely used in many industries because of their high precision, and ensure the size and shape consistency every time. This is so that everything fits together like peas in a pod. They are also fast in their operation, which means they can create a lot parts within seconds saving cost. Due to their strong stature, the flat end brushes can also be washed many times without losing shape or quality.

The 7 production processes are tech support, quality control, mold-making casting, die-casting and surface treatment. Our company boasts 150 - 4000 tons of fully automatic cold chamber die-casting island production lines 60, as well as advanced precision machine centers that are more than 600. The company also has dozens of large precision instruments and measuring equipment, along with a range of additional services. The annual production of the company is 50,000 tons, and it has the capability of Aluminum die casting mold precision manufacturing and processing.

The products are produced by the company's own facilities. We have all the details about prices, ranging from raw materials to production and even services. The company is Aluminum die casting mold with more than 20 die-casting industry experts and over 80 mold professional engineers. We can provide molds and production solutions for our customers. Our product design is customizable. It is able to provide the conditions needed to produce small batches.

Our company was Aluminum die casting mold in 2006, specializing in traditional cars, innovative energy vehicles, telecommunications inverter, photovoltaic energy storage rail transit, medical aviation, as well as other custom aluminum alloy die-casting components and precision machining and general industrial components. We support 24-hour human online support and communications in minority languages. We can also provide a service team to connect with a project.

We have three production centers: Aluminum die casting mold auto part casting plant, Suzhou Jincheng Precision Casting Plant, and Xuzhou Jincheng Precision Casting Plant. The assets total exceed 1 billion Yuan and covers an area of 300 acres. Our plant covers 180,000 square metres. The company has more than 600 CNC machines with more than 60 vertical machining centers and complete electroplating and spraying equipment. We're dedicated to providing our customers with high-quality precision machining customized services.