CNC carving allows you to produce intricate and beautiful designs on wood that would be almost if not completely impossible for a human hand. CNC machines also come in all types and sizes. Both the machine is versatile enough to fit on your workbench or table top, while others are industrial-grade that can just power through hard lumbers easily - great for large projects.

The reason CNC carving is such an awesome thing to do, is because it can be accurate. I share this experience because with computer software, you can design something as intricate and detailed as a kohl liner pattern (for example), it will be beautiful every time. This degree of precision is particularly handy when creating multiple identical designs, as every design can be replicated identically.

One of the other great benefits about CNC carving is that it can be done much more quickly than sat on your bench for days doing traditional hand carven work. Whenever you are actually collaborating with a CNC equipment it can end up along with the inscription at an even more better means contrasted to carry out through palm as well so in much less opportunity. It is evident that you will be able to manage more projects and produce a lot of carvings in no time at all, thereby excellent for both hobbyists as well as professional woodworkers.

For one, you design work on soft software and use sophisitcated tools to carve the wood. As the finish product, all you need to do is upload of your design into CNC machine then it carves everything as neat as you made. This guarantees your tailor-made item to be precisely what you desire it, allowing for a more meaningful creation of the ideas that are in mind.

Simultaneously, this buzz-worthy technology is making room for new and exciting thoughts in the woodworking trade as well. Woodworkers are able to design things that at one point were thought of as impossible by using computer software. This has undoubtedly opened up some incredible new advancements for woodworking, and we can expect to see a whole lot more in the future as technology continues to improve.

The unique quality about CNC carving is that it basically blends modern technology with conventional wood workers skills. It is the machine that does most of the carving work, but for producing a beautiful piece at last the woodworker should also need to have excellent knowledge about basic woodworking principles.

Working with wood is an art and something all workers, truly everyone knows. Although the work of CNC machines can certainly boost quality, it is ultimately up to the craftsman to design woodwork that appeals aesthetically and functionally. An experienced woodworker can use CNC carving to combine the accuracy of modern technology with traditional woodworking, making exquisite pieces that will last a lifetime.

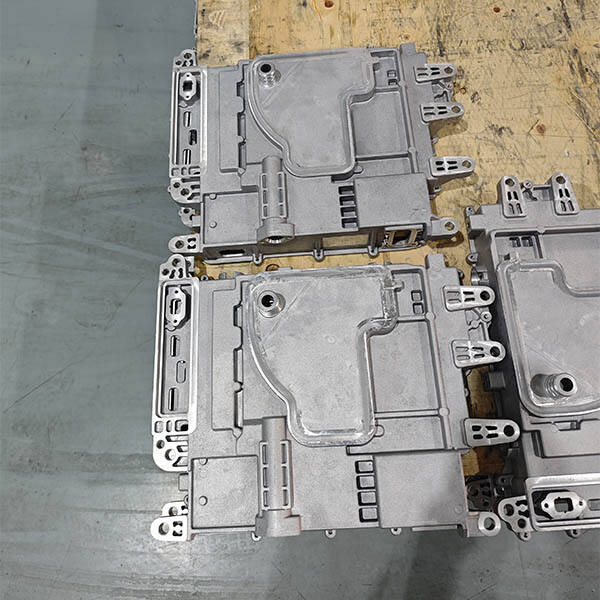

We have three production centers: cnc carving auto part casting plant, Suzhou Jincheng Precision Casting Plant, and Xuzhou Jincheng Precision Casting Plant. The assets total exceed 1 billion Yuan and covers an area of 300 acres. Our plant covers 180,000 square metres. The company has more than 600 CNC machines with more than 60 vertical machining centers and complete electroplating and spraying equipment. We're dedicated to providing our customers with high-quality precision machining customized services.

The seven production processes include the following: technical support, quality control, mold-making die-casting, machine production and surface treatment. Our company cnc carving 150 - 4000 tons of fully automatic cold chamber die-casting production lines 60, and advanced precision CNC machining centers with more than 600. The company also owns a plethora of high-precision instruments and measuring equipment, as well as various additional services. Its annual production is 50,000 tons and it's able to do precision processing and production.

The goods are made in their own factories. We provide all the information regarding prices, from raw materials through production and services. More than cnc carving expert mold engineers and 20 experts in die casting are on hand at the firm. We can supply molds as well as production solutions for our customers. Our product design is flexible. It can provide conditions to produce small batches.

In 2006, our business was established in the year 2006. We are cnc carving in die-casting aluminum alloy pieces as well as precision machining and general industrial components. We provide online human service all day, every day. We also communicate in a variety of languages. We can also offer a team of service representatives to work with your project.