If you have to make a product that fits the factory furnishing and use them on other sites, things need to be precise with no errors then CNC Grinders are like future thing in Grinding technology. When using conventional ways, it will be likely that a person can make mistakes during the grinding process and for this reason more men have chosen to use CNC grinders because they ensure perfection throughout. As a result, the end product would be far more accurate and consistent than if you were to make it using an ordinary grinding machine as was done by humans.

These machines work better and faster than any regular grinding machine. This saves time (since the computer can move the machine at very high speed for accurate tool changes) This fast and precise operation allows many more the same amount of time materials to be ground. This is very crucial when producing products as it implies one can manufacture more items without the need for added time.

CNC Grinders Are Versatile : CNC grinders are versatile machines and can offer exceptional performance with various materials. This is a kind of machines where you should cheat regulars, and use this one for hard or impossible to grind parts. As an instance, harder materials including some metals or plastics can be easily machined. The versatility lies in their area of applications and hence they are really useful for the various industry types starting from the automotive to electronics industries.

A CNC grinder can be of great assistance to you in this simply because it helps with the creation of your services and products. Not only can these machines render objects in the tightest of parameters, this feature also ensures that your end products appear relatively similar to one another when it comes to size and shape. It orders all of your products put to better position together or sell.

CNC grinder machines can be adjusted to work on multiple materials as they have the best flexibility for different levels of technique. This versatility will make a single machine serve many purposes which means you only need to pay for one and save time. A CNC grinder can be utilised for a variety of jobs, such as stainless steel-steel-carbide-centring materials and rigid supplies; instead complete grinding machines are necessary to obtain the same result.

When we need a focused work CNC grinder machines are best to get result true in the matter of quality. These machines are practical and accurate. Which will result in better and more reliable end products. The use of a CNC grinder will provide customers with the strong reputation that comes from using better products and delivering results in less time than human hands could achieve.

A CNC grinder machine Make complex parts in batch Format with while relative ease. This enables you to create more intricate and non-standard things than any normal grinding machine would. A CNC grinder can just as effectively achieve this, making it possible to provide designers with more exciting products including curves or angles if you need a special part.

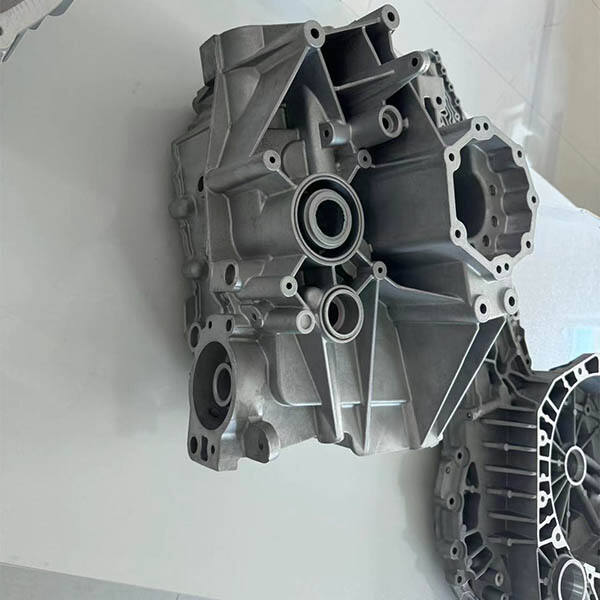

Our company was established in 2006. was founded. We are specialized in die-casting aluminum alloys as well as precision machining and cnc grinder components. We support 24-hour human online support and communications with minorities in a variety of languages. Additionally, we have the service team to help with the project.

The product is manufactured by their own factories. From the purchase of raw materials to further processing and production services we provide cnc grinder details. The company is equipped with more than 20 experts in the field of die-casting and more than 80 mold professional engineers. Our product design is flexible, we can design molds for our customers and offer solutions for production. It will provide the right conditions to produce small batches.

We own three major production bases, Weitang auto parts casting plant, cnc grinder Jincheng precision casting plant, Xuzhou Jincheng precision casting plant. The total value of the assets is more than 1 billion dollars, covering an area of nearly 300 acres, plant area of 180,000 square meters. The plant has more than 600 CNC machine tools, more than 60 horizontal machining centers as well as complete electroplating and spraying equipment. We're committed to providing our customers with the highest quality precision machining customized services.

7 production process, technical support, quality inspection, mold making die-casting production, production of machines cnc grinder, and supporting facilities. Our company boasts 150 - 4000 tonnes of fully automated cold chamber die-casting island production line 60, and advanced precision machining centers more than 600. The company also owns a plethora of high-precision measuring instruments and equipment and a variety of ancillary services. The annual production of the company is 50,000 tons and it is able to perform precise processing and production.