NC is the abbreviation of Numerical Control. A unique technology enabling machines to move extremely accurately to make specific components These parts are incorporated into many of the daily life things which we use such as cars, phones and even food processors. The CNC technology is accurate as it follows the programs of computer which are written in a very correct manner. This allows the machines to produce perfectly fitting parts, an absolute rarity in fields where everything is a step from calibrating.

Parts that come out of our CNC machines must be accurate. If parts are not produced precisely enough, they may malfunction or be assembled in the way we would expect. This can be problematic, especially in such cases as machines or vehicles where is each part needs to connect properly. This is great because CNC technology can be programmed to barf out parts that are hundreds time more accurate and also perfectly sized. This is done to help ensure that the parts are first properly fitted so as not to affect how it will function once this product has been made.

How CNC Precision Accuracy Helps Generate the Right Parts In addition, this technology can build parts so much faster than a person could by hand. Companies love the speed as it allows them to churn out more products on a shorter timescale. This makes it possible for companies to manufacture numerous identical parts through the use of CNC machines. This uniform driving approach keeps the quality high, so it is less likely for products to be defective. Parts produced in uniform ways also simplify assembly into the finished product.

The single largest advantage of CNC machining is efficiency, which ultimately also leads to a decrease in wasted materials. Less waste material is produced when the machines are accurate in making parts. The reason for this is because when there are fewer wastes, companies do not need to buy so much of the raw material and this does good justice to their budget allowances. It also helps preserve the environment because less material is used, thus creating lesser waste.

They have the additional benefit of working 24/7. This allows companies to create numerous parts in very little time which is highly productive. It also allows us to better service our customers through quicker production of more parts. CNC technology can also be used to produce parts, this way reducing mistakes while making the components manually. Companies Save Time and Money — Without errors, companies do not waste time fixing mistakes or re-fabricating sections.

Some of the key methods in CNC machining are applied to ensure that parts produced are exact. For one, there is a technique called "tool offsetting. So that gives the process of adjusting the tool making part to be taken care without machining small changes in material being used. This modification guarantees that a final piece will be produced correctly although the material is somewhat unlike.

The next way of doing it is called "fixture design. " (This often means fabricating a fixture to support the part during fabrication. This helps hold the part still and accurate during the build process thus it will not move in your operation. Correct fixtures you should use to maintain accuracy while machining

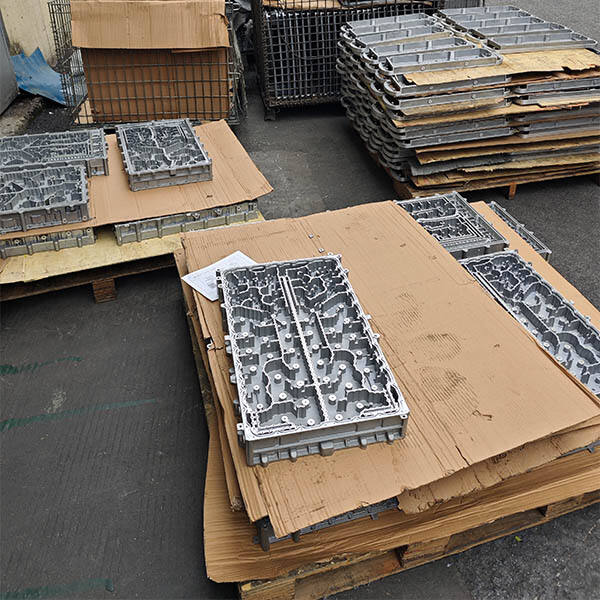

In 2006, our business was founded. We specialize in die-casting aluminum alloy components as well as precision machining and general industrial components. We support 24-hour cnc precision service online and also communication with minorities in a variety of languages. Additionally, we have the service team to help with a project.

We own three main production centers Weitang auto parts casting plant Suzhou Jincheng precision casting plant cnc precision precision casting plant The total value of the assets is more than 1 billion yuan covers the area of almost 300 acres with a total area of 180 000 square meters The company has more than 600 CNC machines including 60 horizontal machining centres with complete electroplating spraying and testing equipment We are committed to providing our customers with high-quality precision machining and customized services

All of our products are produced at the facilities of their cnc precision companies. We have all the details on pricing, from raw materials to production and even services. More than 80 mold engineers as well as 20 die-casting experts are on hand at the firm. Our product design is nimble, we can design molds to meet the needs of our customers, and also provide solutions for production. It is suitable in small-batch production.

7 production process, technical support, quality inspection, mold making die-casting production, production of machines cnc precision, and supporting facilities. Our company boasts 150 - 4000 tonnes of fully automated cold chamber die-casting island production line 60, and advanced precision machining centers more than 600. The company also owns a plethora of high-precision measuring instruments and equipment and a variety of ancillary services. The annual production of the company is 50,000 tons and it is able to perform precise processing and production.