Hi there! In this article, we shall discover a hugely significant phase in the sphere of how CNC performs known as Working. You are probably wondering, what is CNC? Well, let me explain! CNC- Computer Numerical Control In other words the cutting and shaping of different materials are carried out by a machine with the aid of computers. So, that is everyone from factories where thing is made, to airplanes which fly in the sky and even hospitals for their medical tools.

CNC machines are so valuable in part because they have the capability to cut very precisely. It is zeroed..., which means they do cut extremely well and nearly make no mistakes on cutting. This analogy demonstrates the precision in combining two pieces of a puzzle down to fine detail. This is crucial in the case you are making components that require exact fitment together such as parts of a toy or parts for an automotive. Cutters are the tools used by CNC machines. These cutters are very sharp and they move in different directions according to the instructions by computer. The computer then instructs the machine on exactly where to cut and how deep. This ensures every cut is identical, ensuring exceptional products.

CNC machines have to be well looked after in order for them to give their best effort. This means its users should clean them periodically and also oil the blades, just like how we take care of our toys or bikes. If worn out parts are making an appliance to not work then they should be replaced as well. It is very specific to operating a machine right and seeing that every cut should be same as other. This thing wears fast, and those easy repairs become deeper repair capacity; aka more ways for the rotation to get interrupted while not necessarily able to achieve cuts as precise. Not only is this wasteful and time consuming, it does no one any good.

There is a variety of types of materials which can be used to construct an item while using CNC machines. Metals, plastics or wood are the most common materials. Every material has its own specific properties that make it unique, for example how robust or flexible it is. Different things is needed for different projects, so it's good to think about what material you want. For instance, if a part has to be strong and durable the material that is used can also mean steel so as it very tough. For a part that will be lightweight and need to carry, something like Nylon may make more sense due to its light weight and bendy nature. Knowing about these materials can help people to make better decisions during their projects.

CNC + fast and efficient Besides precision, speed of the CNC machine is one more GRADE A criterion. Efficiency: doing things right and in the briefest time possible without wasting resources (i. e.: it will take you a very long time to open your own bakery, or buy one of hundreds possible franchise-bakeries, however all this costs money either way). Here Are A Few Things You Can Try To Speed Up Your CNC encounters. These are special cutting tools, which are capable of separating materials in no moment at all. Alternatively you need two tools and the cutting should be faster. While also improving it so that the machine works more efficiently. Anyway the main thing to take away from all of this is that less code to write and read means more work done in less time, which everyone (well most) likes!

CAD/CAM software is the best way for CNC machines. CAD is computer-aided design and CAM Computer-Aided Manufacturing. The software is specifically designed for engineers and designers to create detailed 3D models of parts or products, which can then be used in geometry-based problem solving. And then they can directly send them to the CNC machine to be made. This will save you tons of time AND produce more accurate work. The software can also reduce waste in disposal by maximizing use of the material and not wasting any aspect).

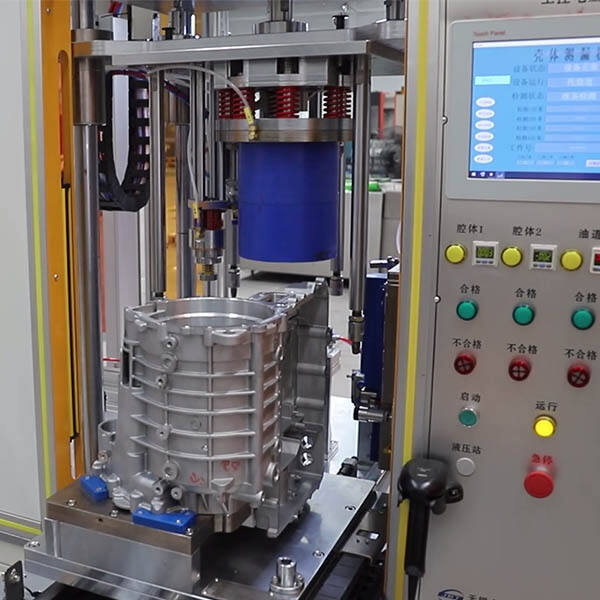

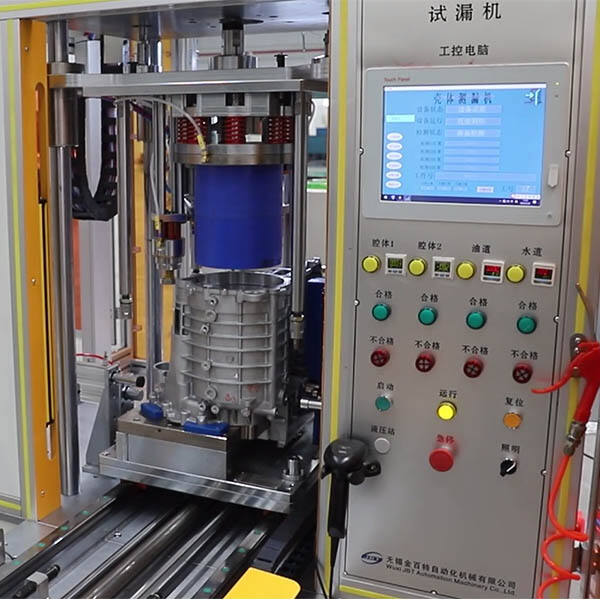

We own three main production centers Weitang auto parts casting plant Suzhou Jincheng precision casting plant cnc working precision casting plant The total value of the assets is more than 1 billion yuan covers the area of almost 300 acres with a total area of 180 000 square meters The company has more than 600 CNC machines including 60 horizontal machining centres with complete electroplating spraying and testing equipment We are committed to providing our customers with high-quality precision machining and customized services

All of our products are produced at the facilities of the cnc working they belong to. We provide all the information on pricing, from raw materials through production and services. The company is equipped with more than 20 die-casting industry experts and more than 80 mold professionals engineers. We offer molds and production solutions for our clients. Our product design is flexible. It can be used in small-batch production.

In 2006, our business was established in the year cnc working. We specialize in die-casting aluminum alloy components as well as precision machining and general industrial components. We offer 24 hours of human-to-human online service as well as communication with minorities in a variety of languages. We also have a service team to connect with a project.

7 production process, technical support quality control, mold production, die casting production, machine production, surface treatment process, supporting facilities. Our company is equipped with 60 modern precision machining centers and fully automated cold chamber island die-casting production lines ranging between 150 and 4000 tonnes. The company also has dozens of large precision instruments and measuring equipment, as well as various related services. The cnc working production of the company is 50,000 tons, and it can perform precision manufacturing and processing.