Steel implants are already light, and they're only going to get better from here... Not that steel would be our first choice for printing materials: 4 lbs a DAY limit at this stage! Phase Two we believe will break more limits on the types of material with known applications in orthopaedics. When things DO start getting made out of Aluminum though today (and often!) one very good way is something called die-casting alloys; We'll let 'em catch up then weigh other implications afterwards? These are unique materials which help in creating diverse range of aluminum parts and that too effortlessly. Unlike other materials used in the manufacturing process, these alloys have numerous great advantages.

Strength - The biggest benefit of die-casting alloys is probably their strength. That means parts made from these sort of alloys are not likely to break or wear out, even over time. Those components can withstand huge amount of pressure and stress due to their strength. Another great thing about die-casting alloys is they are very strong, keep an eye on to work yet again and look new for many years. This durability means that they are suitable for a lot of everyday products.

Our high-performance aluminum alloys are a unique cast die-casting alloy that is not only better for the environment, but also offers additional advantages over conventional die-cast materials. It is constructed using premium materials and they are the superalloys which have a very high content of nickel as these components require to be strong enough for lasting long hours. They are great for tougher applications that demand strength and durability.

High performance aluminum alloys are extremely lightweight. They are effectively able to create products that would be orders of magnitude lighter than if they were made from other materials. Heavy-duty motorsport aluminum alloys are used to save costs on high performance components: a part made from the lightest cast capable alloy may weigh 45% less than it did before, whether such constitutes weight savings---stripping or not. This is particularly crucial in the automotive sector, with lighter parts helping to improve fuel efficiency and speed.

Aluminum components can be manufactured from variety of Aluminum alloys with different Die-casting processes. There are different types of alloy which possess their unique characteristics and benefit being used for various applications. This variety enables manufacturers to select the right alloy for their specific applications.

A View 92 - This is another type of die-casting alloy. This is an amalgam that resists rust and corrosion better than any other. So they can be used to produce parts that will interact with moisture or other detrimental chemicals without damage. These qualities make A360 an ideal choice for outdoor applications or parts that might be exposed to water.

Parts manufactured by the machining or welding process consume a large amount of times and cost. Such techniques are time consuming and consists of several steps. However, die-casting makes parts much faster and for a lower price. It is this cost-effectiveness that probably most attracts companies who want to make quality parts on a budget.

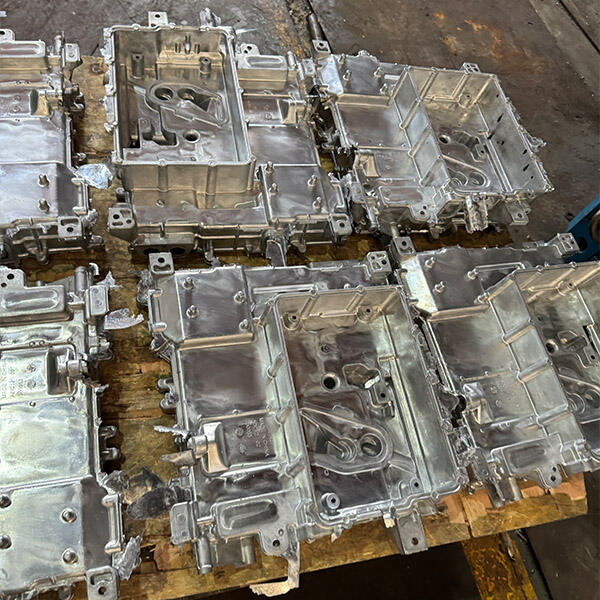

7 production process, technical support, quality inspection, mold making die-casting production, production of machines die casting alloys aluminum, and supporting facilities. Our company boasts 150 - 4000 tonnes of fully automated cold chamber die-casting island production line 60, and advanced precision machining centers more than 600. The company also owns a plethora of high-precision measuring instruments and equipment and a variety of ancillary services. The annual production of the company is 50,000 tons and it is able to perform precise processing and production.

The die casting alloys aluminum was founded by a group of people in 2006. We specialize in traditional automobiles, new energy vehicles, telecommunications photovoltaic energy storage, inverter rail transit, medical aviation, as well as other custom parts made of aluminum alloy, as well as precision machining and general industrial parts. We provide online human service throughout the day, and communicate in minorities languages. We also can provide a team of service representatives to work with your project.

die casting alloys aluminum of our production sites: Weitang auto part casting plant, Suzhou Jincheng Precision Casting Plant, Xuzhou Jincheng Precision Casting Plant. The total assets are more than 1 billion Yuan and covers 300 acres. The plant is spread over 180,000 square meters. The company boasts over 600 CNC machines and 60 horizontal machining centers as well as complete electroplating and spraying testing equipment. We're committed to supplying customers with professional precision machining and customized services.

The products are produced by the company's own facilities. We have all the details about prices, ranging from raw materials to production and even services. The company is die casting alloys aluminum with more than 20 die-casting industry experts and over 80 mold professional engineers. We can provide molds and production solutions for our customers. Our product design is customizable. It is able to provide the conditions needed to produce small batches.