This is done by producing an extruded aluminum profile, where the aluminum material itself pass under stress while being contained in a tool die that models it into a specific shape. It feels almost like rolling play-dough snakes. Remember when you used to make shapes with play-dough by pushing it through one of those tubes that had different shaped holes? That is also how aluminum profile works. Jincheng aluminium engine block profiles are just as the name implies, profiles made of aluminum that can be used for a variety of things from window frames to railings and even furniture. Now, let us all discover few amazing facts about extruded aluminum profiles.

LightweightAnother great benefit of using aluminum profiles is their lighter weight. They are very easy to detach and transport, which makes them highly functional. But they are also rigid, so that can take a lot of weight without breaking or bending. Isn’t that amazing? This is wonderful because it means they will wear well without breaking down, and be relatively little upkeep.

It always great to be able to make a product perfect for yourself as you can. It aluminum ls block profiles can be customized, which is what makes them fun! We can shape them at will so that they serve the particular project you have in hand. This allows you to have a profile that, well for me, is cool because I can say this rectangle here should be 9 inches and nobody will tell me it's not or no its product branding related. They can even paint it in a variety of colors to fit your design vision. How cool is that?

Aluminum is chosen for making extruded profiles for a number of reasons. One, Jincheng mould for aluminium casting is both abundant and easy to work with so it can be a great choice for lots of projects. And, being lightweight as well it is easier to transport and work with compared other heavier metals. Aluminum has a lower melting temperature than many other metals, significant financial production and less energy required to produce.

A great thing about aluminum is that it will never rust. So it is a good stuff and suitable for outdoor use or in damp locations like bathrooms, kitchens. Aluminum is also non-magnetic which make it ideal for applications that you don't want magnetic fields to effect aluminum die casting certain components. But we would prefer not to be succumbed to the images of magnetism on our phones or computers yeah?

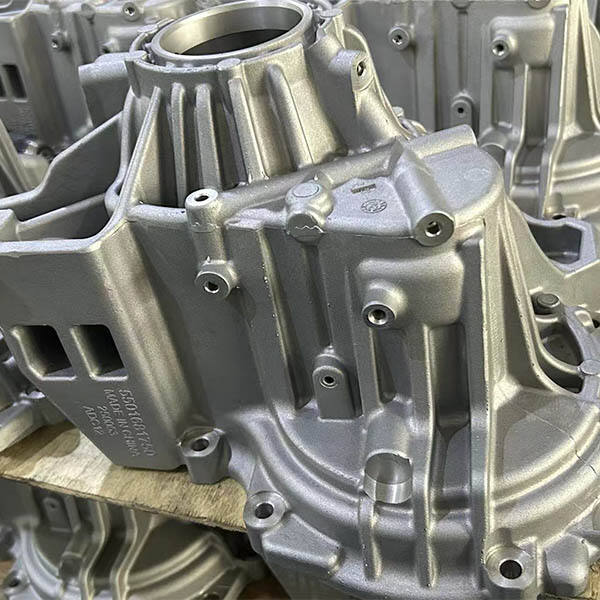

In order to ensure the profiles come out as good quality extrusions when we are making an aluminum profile for our clients, there is a process that will be followed. The Jincheng aluminium die castings profile can be any shape and size you like, which we covered in an earlier article. We then select the appropriate aluminum alloy which has a few different forms, and each is tailored for its own unique characteristics. When choosing the right alloy, we take into account strength properties and surface finish characteristics as well as other factors.

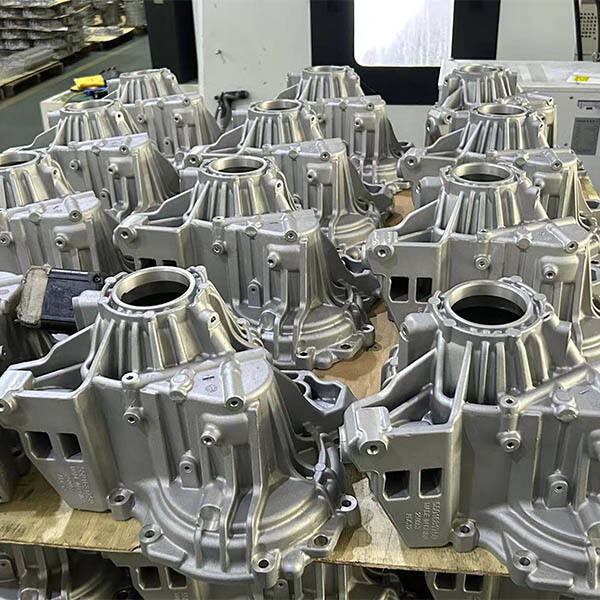

7 production process, technical support, quality inspection, mold making die casting production, machine production surface treatment, and supporting facilities. Our company has Extruded aluminum profiles machining centers, completely automatic cold chamber island die-casting production lines ranging from 150 - 4000 tons. The company also has various ancillary facilities and numerous large-scale precision measurement equipment and instruments, with an annual production of 50,000 tons of aluminum alloy die casting parts and parts research and development production and precision processing capabilities to get the impact of large-scale production.

In 2006, our company was founded. We are specialized in die-casting aluminum alloy components in precision machining as well as general industrial parts. We provide online human service Extruded aluminum profiles and communicate in minorities languages. We also can provide a service team for your project.

We have our own 3 major Extruded aluminum profiles, Weitang auto parts casting plant, Suzhou Jincheng precision casting plant, Xuzhou Jincheng precision casting plant; the total asset size has exceeded 1 billion yuan and covers an area of more than 300 acres, and has a plant space that is 180,000 square meters. The plant has over 600 CNC machines with more than 60 vertical machining centers as well as complete electroplating, spraying and testing equipment. We offer professional precision machining solutions that are customized to our customers.

All of our products are produced at the facilities of their Extruded aluminum profiles companies. We have all the details on pricing, from raw materials to production and even services. More than 80 mold engineers as well as 20 die-casting experts are on hand at the firm. Our product design is nimble, we can design molds to meet the needs of our customers, and also provide solutions for production. It is suitable in small-batch production.