The gearbox bell housing plays an important role in a car as it helps the engine to work with wheels. It works similar to a shield that guards clutch and flywheel which are responsible for the power-trains of an engine so on this level, we can say transmission casing is one step forward. The bell housing connects the engine to the transmission, and keeps everything in place. It also keeps dirt and junk from getting into the transmission, which will make your car not work good.

Thrust Bearings Can Affect Clutch And The Gearbox Bell Housing On Your Car

One of the front-and-center things to make your car go is its gearbox bell housing. If you find that the car is making a strange noise when driving, has trouble shifting gears or initiates rough gear shifts at initial belts housing failure. Hell, a bad bell housing can even foul enough to stall your car.

In other words, it cannot be stressed enough that you still will need to keep an eye on your gearbox bell housing warnings just as always. Signals, sounds (shifting hard to gears or noise) that something ain't right. Car not driving like it used to Any Ways to Determine a Mechanic Should Check Car?

Sometimes the bell housing can be repaired if the problem is caught early in its failure process, without requiring replacement. LocationAnd the damage could have been bad, necessitating a new bell housing. You should replace or fixing it only with the help of trained car expert which guarantees that its done properly.

A coupe of things to keep in mind when looking at a gearbox bell housing for your car. To begin with check, that it is compatible with your car model Also, ensure it is made form durable materials to serve you for a long period.

Consider also how you are going to drive Grab a bell housing; maybe, if you are going to race this or drive fast. But if you will use it mainly to drive yourself to school or work, a standard one would do.

ProcessorsSoC : What Exactly They Are and Why Do You Need Them?

Gearbox bell housing which is built in segments. The bulk of it is an empty shell that fits around the clutch and flywheel. It is normally of some sturdy metal and sits next to the engine.

The Bearing retainer inside the bell housing This prevents the input shaft from sliding back and fourth. Bearings inside the hole, completed by a holder kept with snap ring that can be removed to undertake repairs or replace part.

When it comes to a working car, you have the gearbox bell housing. If you know how it works, your car will perform better. If you notice any problems, see a car specialist as soon as possible.

A gearbox bell housing, especially the regular maintenance of it is essential to keep your car in good working order. Looking for any signs of wear and tear such as odd noises or trouble changing gears are all ways to get a head on issues even before they appear.

If you observe any strange conditions it is important to have a qualified mechanic look at your car. They can repair or replace the bell housing and help to diagnose what troubles might be afoot.

As a result, getting to grips with the types of gearbox bell houses you can choose for your car makes keeping it running at peak performance even more of an essential endeavour. When it comes to something like a bell housing where performance is the ideal, making sure you pick out the right one can dramatically impact your time in those seats.

Looking further into bell housings as a feature for gearbox, the components are varied and yet needed for smooth operation. Every part-from the heavy-duty main body that houses your clutch and flywheel, to the critical bearing retainer which secures shaft alignment-plays a crucial role in how well your car runs.

Understanding the basic anatomy and function of these parts will help you to appreciate more the gearbox bell housing's importance in your vehicle. All of this simply means you can now have the knowledge to pay special attention on how best to keep...... this important component in tip top shape, and help prolong its life along with increasing your cars transmission system efficiency.

Staying informed and paying attention to your gearbox bell housing, remember will be able to prevent expensive repairs down the road having a smooth driving way better. Therefore, the next time you drive your car out from your driveway be sure to remember about this piece which also goes a long way in maintaining top condition for all cars on road.

In 2006, our business was established in the year gearbox bell housing. We specialize in die-casting aluminum alloy components as well as precision machining and general industrial components. We offer 24 hours of human-to-human online service as well as communication with minorities in a variety of languages. We also have a service team to connect with a project.

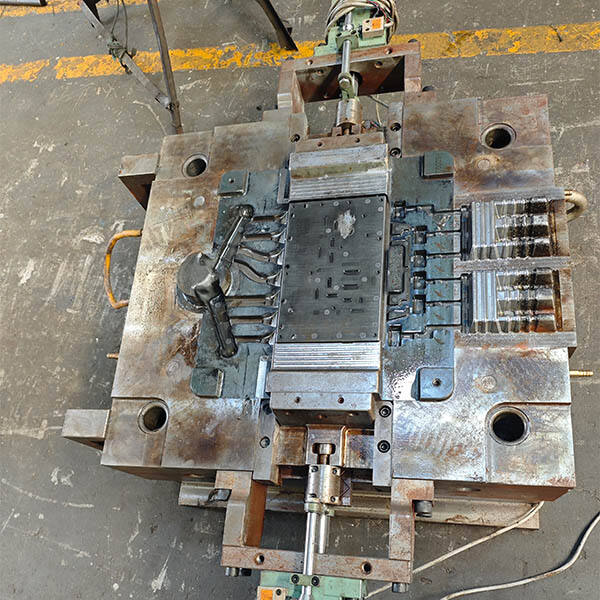

All of our products are produced at the facilities of the gearbox bell housing they belong to. We provide all the information on pricing, from raw materials through production and services. The company is equipped with more than 20 die-casting industry experts and more than 80 mold professionals engineers. We offer molds and production solutions for our clients. Our product design is flexible. It can be used in small-batch production.

7 production process, technical support, quality inspection, mold making die casting production, machine production surface treatment, and supporting facilities. Our company has gearbox bell housing machining centers, completely automatic cold chamber island die-casting production lines ranging from 150 - 4000 tons. The company also has various ancillary facilities and numerous large-scale precision measurement equipment and instruments, with an annual production of 50,000 tons of aluminum alloy die casting parts and parts research and development production and precision processing capabilities to get the impact of large-scale production.

We have our own 3 major gearbox bell housing, Weitang auto parts casting plant, Suzhou Jincheng precision casting plant, Xuzhou Jincheng precision casting plant; the total asset size has exceeded 1 billion yuan and covers an area of more than 300 acres, and has a plant space that is 180,000 square meters. The plant has over 600 CNC machines with more than 60 vertical machining centers as well as complete electroplating, spraying and testing equipment. We offer professional precision machining solutions that are customized to our customers.