If you walk around a machine shop, or anywhere with large spinning machinery that is very noisy3D KPI and GDD? They fabricate very tiny metal parts that need to fit together in the thousands, i. e. ultra fine micro structure.. And big stuff is made up of thousands of bits and pieces - all that tiny cogs, and wheels, levers; spurred together into one holistic structure in themselves often as complex or intricate at heart.

I mean, when it comes down to it, a precision machine shop is just one giant puzzle factory. People come in with pictures or drawings of all sorts of tiny metal things for airplanes and cars, even instruments that doctors use. Workers on shop floors are familiar with large machine tools that make precise cuts and fabricate the metal parts which have to be millimeter perfect. They care about details and get every little part to work well with all the other parts - kind of like the pieces in a game.

As such, a CNC machine is an essential equipment in any precision machining shop. CNC which stands for Computer numerical control. That is a fancy way of saying: an algorithm (a clever computer program) tells the machine what it has to do, step by step. This in-turn makes the parts to be made exactly every-time a run is done using it, for That they are used very suitably with CNC machine. It is the next best thing to having a super smart robot that makes stuff! This all saves time, and of course insures that everything is made exactly as specified which for precision machining this is critical.

Top 8 Skill Set You Need If You Want to Work in a Precision Machine Shop First and foremost, you must be good at math to get a grip on measures of comprehensive calculations. And your hand has to be rock solid with an epic cut each time. Parts are created to be form fitted, just as time is taken with them. The measures the specific sizes of each unit, marking it again for a final check to verify that they are correct before being cut. Just like an artist, but instead of using paint and canvas they use metal and machines to create beautiful pieces.

Most are precision machine shops others not so much also with the new technology most companies stay up to date on every bit of technology out there from lights out machining that way all parts made perfectly for a customer. They often depend on devices similar to 3-D printers, which can create models of pieces to test. That allows them to visualize what the part will physically look like. After that, they take those models and run them through big fancy machines to produce the final components. Every time they pull out the dimensions to ensure, and alter something appropriate once we must - here is how these kinds of technician want it.

Q Have you ever tried to draw a good picture, but struggled because it did not look exactly how you wanted. A good and timely machine shop turns ideas into things. An airplane, car and so forth are into existence only upon people who manufacture them where the original sections fitted which helps their working. Precision machine shops play a major role in this process, making the parts work just as they are supposed to do. This way, you will know your creation can stand on its own two legs and work functioning just like how it was imagined to.

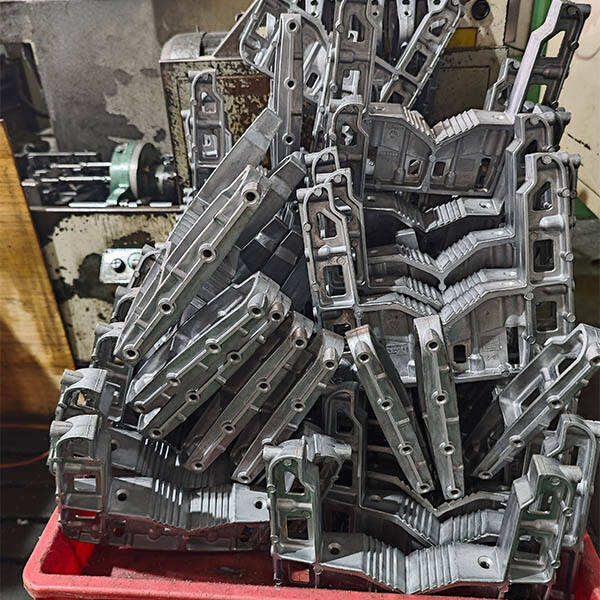

Each product is manufactured at the precision machine shop of the respective companies. We have all the details about prices, ranging from raw materials to production and services. More than 80 expert mold engineers as well as 20 die-casting experts are available at the company. Our product design is nimble, we can design molds to meet the needs of our customers, and also provide production solutions. It is suitable in small-batch production.

precision machine shop of our production sites: Weitang auto part casting plant, Suzhou Jincheng Precision Casting Plant, Xuzhou Jincheng Precision Casting Plant. The total assets are more than 1 billion Yuan and covers 300 acres. The plant is spread over 180,000 square meters. The company boasts over 600 CNC machines and 60 horizontal machining centers as well as complete electroplating and spraying testing equipment. We're committed to supplying customers with professional precision machining and customized services.

In 2006, our company was founded. We are specialized in die-casting aluminum alloy components in precision machining as well as general industrial parts. We provide online human service precision machine shop and communicate in minorities languages. We also can provide a service team for your project.

The seven processes of production are tech support, quality control, precision machine shop casting, die-casting and surface treatment. Our company has 150 - 4000 tons of fully-automated cold chamber die-casting islands production line 60, high-precision machines that exceed 600. It also has dozens of large precision measuring equipment and instruments, along with a range of other ancillary services. The annual production of the company is 50,000 tons and it's able to do precision manufacturing and processing.