CNC هي اختصار لـ Computer Numerical Control. وهي تقنية تجعل برنامج الكمبيوتر هو الذي يتحكم في الجهاز بدلاً من الإنسان. هذه التكنولوجيا تسهم في تسريع تدفق تطوير المنتجات وجعله أكثر دقة واتساقًا. جينتشنغ تصنيع باستخدام الحاسب الآلي CNC تتبع المواصفات أو التعليمات المحددة لها بدقة دون أن تشعر بالتعب، مما يؤدي إلى تحسين جودة المنتجات بشكل كبير

لدينا مجموعة واسعة من مراكز التصنيع باستخدام الحاسب الآلي ذات الجودة العالية في جينتشنغ لإنتاج مكونات بدقة عالية لصناعة متنوعة من القطاعات. بسبب هذه التعليمات، تميل آلاتنا إلى العمل باحتمالات خطأ أقل بكثير. وهذا أيضًا هو كيفية ضمانها لأن كل قطعة يتم تعديلها بشكل مثالي تمامًا وفقًا لما يجب أن تكون عليه.

تتميز مراكز التصنيع باستخدام CNC بإحدى أفضل المزايا لإنتاج مكونات ذات دقة عالية. يتم التحكم بأدوات القطع في الآلة CNC بواسطة برنامج كمبيوتر، مما يمكّن الأداة من تنفيذ قطعات دقيقة للغاية، وفتحات وأشكال. مثل قطع الكيك، يتطلب الأمر لمسة حلوة. وآلات CNC تقوم بهذا العمل بدقة أكبر.

هذه صفة لا تقدر بثمن في العديد من الصناعات، بما في ذلك صناعة الطيران، والطبية، والسيارات، حيث تكون الدقة أمرًا أساسيًا. للحفاظ على رحلات الطيران آمنة وكفؤة، يجب تصنيع محركات الطائرات بدقة عالية جدًا. حتى أصغر انحراف يمكن أن يكون كارثيًا في علم balistics. بنفس الطريقة، يجب أن تكون الأجهزة الطبية ملائمة تمامًا للجسم البشري لتجنب أي انزعاج أو مضاعفات مثل الزرائع والبروستيثكيات. وأخيرًا، يجب تصنيع قطع غيار السيارات بدقة لضمان استمرار المركبات التي يتم تركيبها عليها في البقاء صالحة للسير وتعمل لفترة طويلة.

في التصنيع التقليدي، إنشاء جزء واحد كان يعني العمل مع العديد من الأدوات المختلفة في نفس الوقت. قد يستغرق ذلك العديد من الخطوات وكمية كبيرة من الوقت. جينتشنغ خدمة تشغيل CNC ومع ذلك، تبسط مراكز التصنيع وتسرّع العملية بأكملها. في الأساس، إنها مثل مساعد فائق الكفاءة ينفذ ما يُطلب منه بشكل مثالي.

تقلل مراكز تشغيل CNC من الحاجة إلى التدخل البشري من خلال برمجة الآلة مسبقًا بالمهام التي يجب تنفيذها على الأجزاء. وبالتالي، تصبح كمية الأجزاء عالية الجودة أكثر اتساقًا ويستغرق إكمال العمل وقتًا أقل. توفير هذه القدرة ي자동ize هذا السير العملي بعيدًا عن الأشخاص ليتمكنوا من التركيز على أنشطة أخرى.

بفضل التقدم في مجال CNC جينتشنغ مركز التشغيل العمودي بفضل التكنولوجيا، أصبحت عملية التصنيع أكثر تطورًا وفعالية. نحن نمتلك ماكينات CNC متعددة العمليات قادرة على تنفيذ العديد من الوظائف، وكل ذلك في إعداد واحد. يمكن لماكيناتنا القيام بأنواع مختلفة من العمل دون إيقاف تشغيلها أو تغيير الأدوات باستمرار. على سبيل المثال، يمكنها تبديل أدوات القطع تلقائيًا، مما يوفر الكثير من الوقت ويقلل من عدد الأشخاص المطلوبين في كل خطوة من العملية.

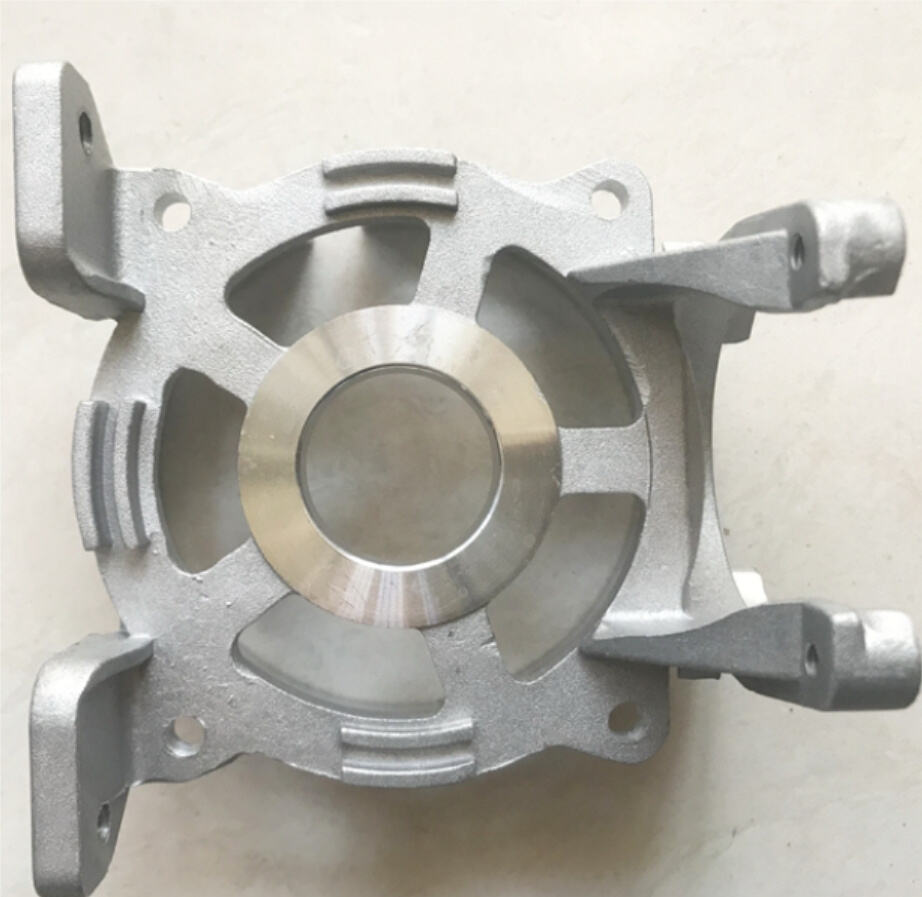

في عام 2006، تم تأسيس شركتنا في مجال مركز التصنيع باستخدام الحاسوب CNC. نتخصص في تصنيع مكونات سبائك الألمنيوم بالصب بالإذابة بالإضافة إلى العمليات الدقيقة للتصنيع والقطع الصناعية العامة. نقدم خدمة عبر الإنترنت لمدة 24 ساعة مع دعم مباشر من البشر، كما نتواصل مع الأقليات بلغات مختلفة. كما لدينا فريق خدمة لدعم المشاريع.

7 عمليات إنتاجية، الدعم الفني، الفحص الجودة، صنع القوالب وصب الإذابة، إنتاج الآلات مركز التصنيع باستخدام الحاسوب CNC، والمرافق الداعمة. تفخر شركتنا بخط إنتاج أوتوماتيكي بالكامل لصناعة السباكة بالإذابة الباردة بطاقة 150 - 4000 طن، وعددها 60، ومراكز تصنيع دقيقة متقدمة بأكثر من 600. كما تمتلك الشركة مجموعة كبيرة من أدوات القياس والمعدات عالية الدقة وخدمات داعمة متنوعة. الطاقة الإنتاجية السنوية للشركة هي 50,000 طن وهي قادرة على تنفيذ العمليات الدقيقة للإنتاج.

المنتجات هي مراكز تجهيز CNC في مرافق الشركات التي تنتمي إليها. نحن نمتلك جميع التفاصيل حول الأسعار، بدءًا من المواد الخام، وحتى الإنتاج والخدمات. الشركة مجهزة بأكثر من 20 خبيرًا في مجال الصب بالضغط وأكثر من 80 مهندس محترف في قوالب الحقن. تصميم منتجاتنا مرن ونستطيع تصميم القوالب للعملاء وتقديم حلول إنتاج. مناسب لإنتاج دفعات صغيرة.

لدينا ثلاثة مراكز رئيسية للتصنيع باستخدام الحاسوب (CNC) الخاصة بنا، ومصنع صب قطع غيار السيارات ويتانغ، ومصنع الصب الدقيق سوزهو جينتشنغ، ومصنع الصب الدقيق شوزهو جينتشنغ؛ تجاوز حجم الأصول الإجمالية مليار يوان، ويغطي أكثر من 300 فدان، ولديه مساحة مصنع تبلغ 180,000 متر مربع. يحتوي المصنع على أكثر من 600 ماكينة CNC، بما في ذلك أكثر من 60 مركز تصنيع عمودي، بالإضافة إلى معدات الكromبلة، الرش والاختبار الكاملة. نقدم حلول تصنيع دقيق مخصصة لعملائنا.