We need to use tools if we are going to build anything with metal because that is the best way it can be done. Vertical machining center is one of the most vital tools which we need in our everyday industrial life. This Jincheng cnc machining is very good on how it cuts and shape the metal into three different shapes according to its size. Imagine a huge robot assistant that will do the tasks we want in our projects, and he does it very quickly with high accuracy. Today, we are going to discover why vertical machining centers play such an important role and how they help us build great things.

Try to cut a small piece of paper with scissors It is a bit of a mission impossible, isn't it? Think of it as the magic pair of scissors that cuts through all papers perfectly without any mistakes. These devices are so accurate that they will be able to perfectly cut even the tiniest of details. One reason a vertical machining center is so precise is because it uses numerous larger and smaller tools, both drills and cutters to gradually take the material down into very defined shapes given that metal-workers are able do this accurately with CNC. This in turn assures that the end result appears before us exactly as we had been picturing it: perfect, blemish and glitch free.

If you are in the business of fabricating metal structures, then time is essential. An item, which requires a lengthy period of time to produce it has higher price. And this is where vertical machining centers are really in own. The Jincheng nc machining is meant to work fast and efficient, anyone looking to spend days, not even weeks using conventional hand tools; it can be done in just a matter of hours with any vertical machining center. In short, you will be able to complete more projects in less time. This will save you money, but also impress your boss and be an example of the many other skills that a Metalworker today can have.

Workpiece: The piece of metal you are cutting and shaping. Metal is expensive and hard to get, so make sure you use this workpiece up. The very nature of vertical machining centers enables you to workflow in a way that suits how most workpieces will be used. It ensures that you do not leave any waste metal in place where no work is done so it allows to create more and get same number of things generated meta-forging mill That kind of seems like a win-win no matter how you look at it in the end, so why not consider that?

Now efficiency is a big word, at the core it getting more work done in less time and with reduced overall effort. Vertical machining centers only can do this incredible efficiency because the actual movements are managed using computer programs. So, these people can work fast and accurate without needing a guide all the time. Jincheng cnc cutting machine is also designed to have an inordinate amount of energy efficiency, thus help you reduce your electric bills. Description: So, these machines not only can help you work faster but they can also save your money.

Operating a vertical machining center is extremely easy this simplifies the best part about programming it. Once you configure it based on your project requirements, all you have to do is hit the button and see ng-behaviors going about its job. With this beast you can take a breath and rest assured knowing that your project is well taken care of. In addition, the vertical machining centers are also very safe to use and need little maintenance so that you do not encounter any problem while working. With a vertical machining center, you can instead have quick and flawless work.

Our company was established in 2006. was founded. We specialize in Vertical machining center aluminum alloy components in precision machining as well as general industrial parts. We offer 24 hours of human-to-human service online and also communication in languages of minority. We can also provide an expert service team to assist with a particular project.

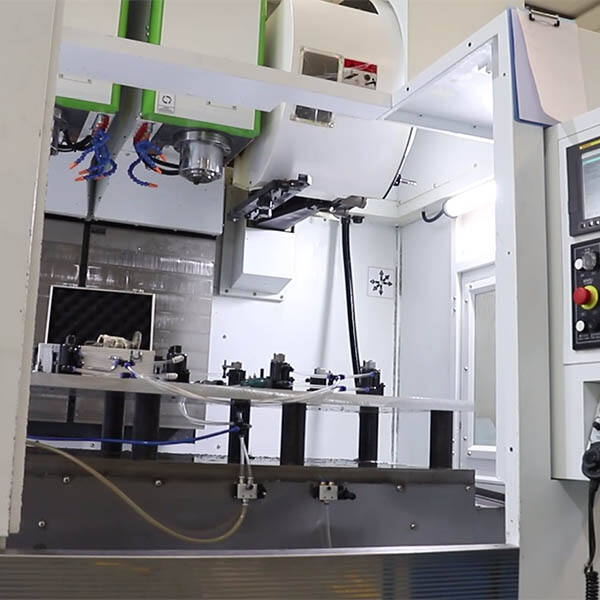

We have our own 3 major Vertical machining center, Weitang auto parts casting plant, Suzhou Jincheng precision casting plant, Xuzhou Jincheng precision casting plant; the total asset size has exceeded 1 billion yuan and covers an area of more than 300 acres, and has a plant space that is 180,000 square meters. The plant has over 600 CNC machines with more than 60 vertical machining centers as well as complete electroplating, spraying and testing equipment. We offer professional precision machining solutions that are customized to our customers.

7 Vertical machining center procedure, technical support, quality inspection, mold making die-casting production, production of machines, processing of surfaces, as well as other facilities. Our company owns 150 - 4000 tons of fully-automated cold chamber die-casting island production line 60, high-precision machine centers that are more than 600. The company also includes ancillary facilities as well as numerous large-scale precision measurement equipment and instruments. They have the capacity of 50,000 tons of aluminum alloy parts for die-casting as well as parts research and development production, as well as precision processing capabilities, to attain the benefits of production on a large scale.

The product is manufactured by their own factories. From the purchase of raw materials to further processing and production services we provide Vertical machining center details. The company is equipped with more than 20 experts in the field of die-casting and more than 80 mold professional engineers. Our product design is flexible, we can design molds for our customers and offer solutions for production. It will provide the right conditions to produce small batches.